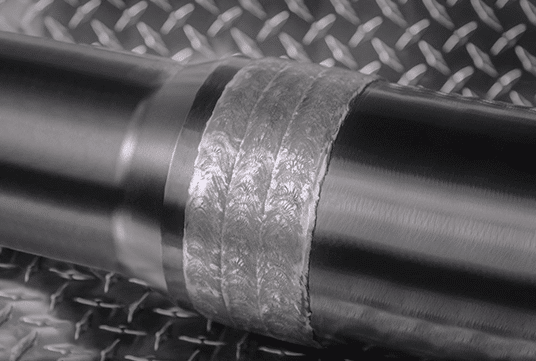

Drill Pipe Tool Joint Protection: Advanced MStar™ Hardbanding Protects Your Investment

Superior Drill Pipe Tool Joint Protection

In drilling operations, protecting your drill pipe tool joints is crucial for operational efficiency and equipment longevity. Hardbanding should also not damage the casing. IGS’s Armacor MStar™ hardbanding technology offers superior protection of the tool joint while being most casing friendly.

Why Choose MStar™ for Your Drill Pipe Tool Joints:

- Industry-leading surface hardness (up to 1100 Vickers)

- Lowest coefficient of friction available (0.11-0.14 against steel)

- Zero field failures record

- Superior casing protection

- Extended tool joint life

- Excellent reapplication properties

The Science Behind the Protection

MStar’s revolutionary amorphous metal technology provides a unique advantage in drill pipe tool joint protection. Under drilling conditions, the material transforms from crystalline to amorphous microstructure, creating an exceptionally smooth, hard surface that:

- Minimizes friction and wear

- Prevents galling

- Protects both the tool joint and casing

- Eliminates common failure points found in traditional hardbanding

Application Process

Our application process ensures consistent, high-quality application every time:

- Precision-controlled application

- Uniform coverage

- Excellent bond strength

- Minimal heat affected zone

- Compatible with all standard drill pipe grades

Reapplication Benefits

MStar™ offers superior reapplication characteristics:

- No need to remove previous MStar™ application

- Excellent bond to existing hardbanding

- Consistent performance across multiple applications

- Reduces maintenance downtime

- Extends overall equipment lifecycle

Applications:

- New drill pipe tool joints

- Refurbishment of worn tool joints

- Reapplication over existing hardbanding

- Open hole operations

- Cased hole operations

Quality Assurance

Each application is backed by:

- Comprehensive quality control procedures

- Full traceability

- Certified welding technicians

- Technical support

Cost Benefits

Investing in MStar™ hardbanding provides significant long-term cost advantages:

- Extended tool joint life

- Reduced casing wear

- Fewer replacements needed

- Less downtime for maintenance

- Lower overall operational costs

IGS Service Commitment

We provide:

- Professional consultation

- Technical specifications review

- Application recommendations

- Post-application support

Whether you’re protecting new drill pipe tool joints or refurbishing existing equipment, IGS’s MStar™ technology provides the most advanced protection available in today’s market. Contact our technical team to discuss your specific application needs.

Contact Us: For detailed specifications or to schedule a consultation, reach out to our drill pipe tool joint protection specialists.