Energy Efficiency and Fuel Savings

Refineries, petrochemical, and chemical facilities can reduce fuel gas use by up to 15%.

Fired Heaters in refineries, petrochemical, and chemical facilities use a lot of fuel. Optimizing the efficiency of the radiant and convection sections of these furnaces delivers fuel savings of up to 15%, resulting in millions of dollars of savings annually.

How Refineries Achieve Energy Efficiency and Fuel Savings with IGS’s Engineered Solutions

Refineries, petrochemical and chemical facilities work with Integrated Global Services (IGS) to evaluate their fired heaters. The evaluation estimates the benefits that can be achieved with the application of one or more of t several innovative technologies: high emissivity Cetek coatings, TubeTech™ cleaning services, and Environmental SCR solutions.

Cetek coating can be applied to the refractory, process tubes, or both, depending on the type of the fired heater and its design and operating parameters.

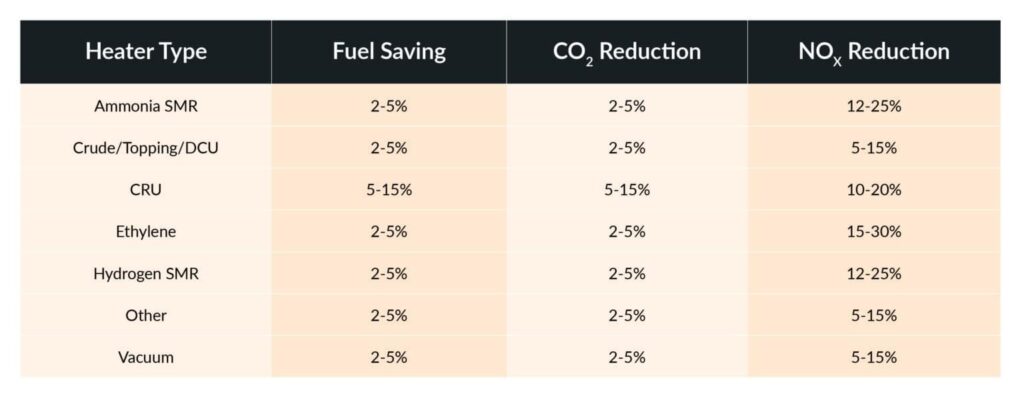

Expected Fuel Savings with IGS Fired Heater Services are:

Improving Energy Efficiency of Fired Heaters and Reformers to Reduce Fuel Consumption

Advanced performance enhancing solutions have created an increased opportunity to reduce fuel use in fired heaters and reformers.

How to Improve Energy Efficiency in Fired Heaters

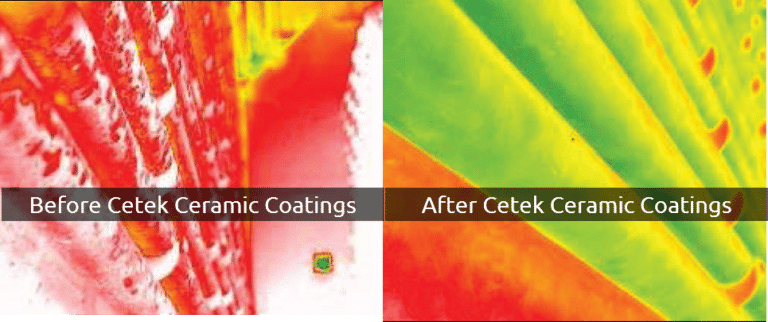

Radiant Section Process Tube and Refractory Coatings

Radiant tube thin-film ceramic coating prevents oxidation and scale growth for the life of the coating.

The high emissivity nature of the refractory coating, in turn, ensures that a maximum amount of radiant heat available is absorbed by the tube surfaces.

The combined benefit from high emissivity coatings applied to refractory and tube surfaces can be as high as 15% increase in radiant section heat transfer efficiency. This increase in heat transfer efficiency leads to significant effects on NOx and CO2 emissions: Lower flue gas temperature leaving the radiant section (bridgewall temperature)

Convection Section Robotic Cleaning Solution

Convection section efficiency can be improved with the use of convection section cleaning. IGS’ TubeTech™ solution utilizes robotic cleaning that achieves a 90%+ clean area with no risks associated with manual/man entry cleaning.

Case Study: Tüpraş Izmir Refinery

Overview

- The average cost of hydrogen production before and after cleaning was calculated at $943.9-919.3 $/t. The production cost of hydrogen decreased by $24.6/t after cleaning and the payback period for the project was less than 60 days.

- The average flue gas temperature decreased from 278°C before cleaning to 220°C after cleaning, meaning that the furnace’s thermal efficiency increased by approximately 3%.

- Steam production increased by approximately 20%, and the generated steam temperature increased by 10°C-15°C.

IGS Improves Energy Efficiency in Fired Heaters

Watch: 13.5% Efficiency Increase in Catalytic Reformer Fired Heater Performance

In this video Larry Emch, Furnace Efficiency Specialist discussed a project where his team audited furnaces and heaters at an oil and gas site, identifying inefficiencies and offering solutions for increased production, including a notable 13.5% improvement, and long-term efficiency. Following the audit, IGS provided payback calculations before embarking on a successful project to address significant scale on the radiant tube, which was causing severe heat absorption problems.