Scale Removal on Live Furnace Leads to Instant Fuel Savings

This case study showcases how IGS’s on-line Hot Tube Descaling (HTD) service removed scale from a live furnace, delivering immediate fuel savings and boosting overall performance at a refinery in Jubail.

High Temperature Scale in Furnaces

In refineries, the accumulation of scale on furnace process tubes can lead to decreased performance, reduced efficiency, and potential safety risks. To address these challenges, the IGS Team implemented a Hot Tube Descaling (HTD) process at a refinery in Jubail. This case study aims to evaluate the effectiveness of the HTD approach and its impact on fuel consumption reduction and overall operational efficiency.

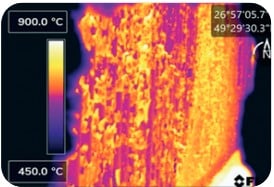

Before HTD: High surface temperatures and reduced heat transfer

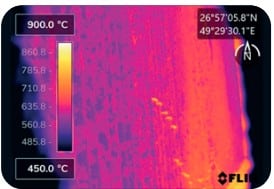

After HTD: Optimized thermal profile, enhanced reliability, and measurable energy savings

Technical Solution

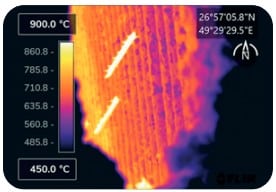

Hot Tube Descaling (HTD) removes radiant section process tube scale and fouling during furnace operation without shutdown. Water-cooled lances ensure continuous scale removal and maximum cleaning while the heater continues to operate. The process utilizes organic abrasive media resulting in no impact on emissions or opacity. Existing inspection ports are used to introduce lances.

- Improves fired heater efficiency by removing insulating scale.

- Reduces tube surface temperature.

- Reduces bridge wall temperature.

- Especially effective in catalytic reforming units.

The organic blasting media incinerates completely during the service, with no effect on the environment. The process is efficient, environmentally friendly, and safe for the removal of years of scale and fouling with no interruption to production.

Process Tube Descaling on Live Heaters

By considering the process tube metallurgy, the team identified that the HTD service was ideally suited to remove the semi-adherent loose scale on the surface.

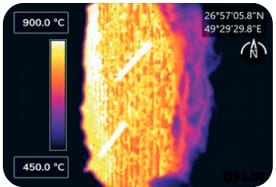

The IGS Team focused on cleaning as much surface area as possible while ensuring the protection of adjacent refractory surfaces from collateral damage.

The team strategically inserted the cleaning lance through inspection doors.

Results and Benefits: Fuel Consumption Reduction

Post-HTTD implementation, the refinery reported a significant 3.5% reduction in fuel consumption.

This translates to substantial fuel savings and enhanced operational efficiency.

Return on Investment Analysis for High Temperature Descaling in Furnaces

The chart in this case study demonstrates substantial returns on the HTD project. Whether through fuel savings or increased throughput, the refinery is poised to realize:

- Payback within five months or less

-

3.5% fuel savings or capacity increase

-

$642,600 extra monthly profit

This analysis emphasizes the cost-effectiveness and profitability of the HTD approach.

Before HTD: High surface temperatures and reduced heat transfer

After HTD: Optimized thermal profile, enhanced reliability, and measurable energy savings

Conclusion

The implementation of the HTD process by the IGS Team at this refinery in Jubail resulted in notable improvements in operational efficiency and performance.

The successful removal of loose scale deposits enabled more reliable tube metal temperature measurements for enhanced safety.

The 3.5% increase in energy efficiency delivered:

-

6-month payback based on fuel savings

-

1-month payback based on capacity increase

This case study highlights the importance of proactive maintenance strategies and showcases the potential of the HTD process in achieving operational excellence and cost savings in refinery operations.

I’m here to help

Larry Emch

IGS Subject Matter Expert

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.