How A Plant Stopped CFB Boiler Tube Repairs From 500 To 0 with IGS SMARTGard®

Boiler Units and Wastage Mechanisms

This US City Hybrid Energy Center operates two 300-MW CFB boilers that burn a combination of coal mixed with up to 20% biomass.

The cladding along the water walls, as with any CFB, requires regular maintenance to rebuild the cladding thickness loss caused by the aggressive nature of ash erosion in these types of boilers. In high corrosion locations in the combustor, the coating can be utilized to mitigate tube thickness loss from this mechanism because of superior metallic properties that prevent further wastage.

PROBLEM

Thermal Spray Cladding applied by a previous vendor was unable to prevent metal wastage. After one year in service, 500 tube repairs were carried out due to insufficient erosion-corrosion protection of tubes.

SOLUTION

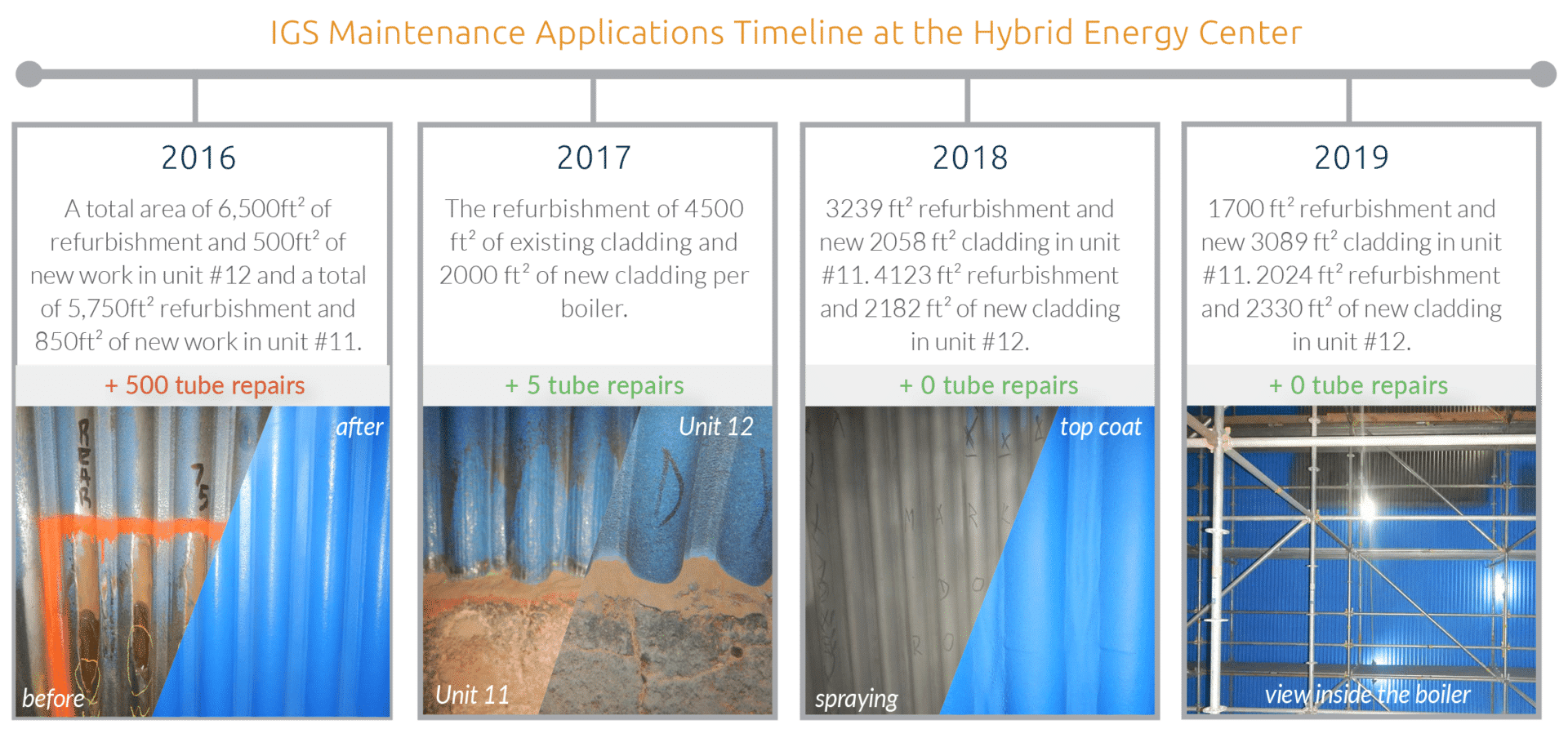

IGS was invited to remedy the problem areas following technology discussions and a mid-year inspection where the extent of the problems were identified. IGS, the asset owner, a 3rd party expert and a mechanical contractor worked as a unit to create a mitigation plan for the vast damage caused by the failure of the other contractor’s thermal spray cladding. IGS’ SMARTGard® service which uses HVTS Alloy Cladding was first installed in 2016 during a major rehabilitation project. Since the IGS cladding was applied, only 5 tube repairs were done in the first year. No tube repairs were needed since.

Inspection Identifies Significant Wear and Damage

Inspection of a previously applied protection is a critical part of any project. During the inspection, IGS utilized both visual and magnetic lift-off (MLO) techniques to record any low readings.

Areas that were below the minimum specification were noted and recorded. A considerable amount of the existing coating was significantly eroded. In many cases, it had worn through to the substrate and in the worst cases had allowed significant tube gouging to occur. The amount of defects observed was significantly greater than expected, with 500 tube repairs performed.

Working in Partnership

The asset owner and IGS worked closely to mitigate problems during 2016. IGS laid out a 2-year plan to stabilize the existing problems, proactively protect future problem areas, and forecast maintenance spend. The plant made investments in solving the problems the correct way and addressing wear areas proactively from Day 1.

2015 Cladding Failure – Result of Multiple Contributing Factors

Improper Installation and Surface Preparation

- Inadequate preparation and incorrect application parameters led to localized spalling and delamination of the competitor’s coating.

Breakdown in Quality Control

- Failure to detect poor bond integrity.

- Overlooked areas where cladding did not meet required specifications.

- Missed sections where cladding was agreed to be applied but was omitted.

Insufficient Application Procedures

- Poorly executed tapered transitions.

- Inconsistent adherence to nominal thickness requirements.

- Tie-ins from one cladded section to an adjacent section.

Lack of End-User Alignment and Specification Management

- No clear expectations set regarding future refurbishment needs.

- Absence of a customized specification tailored to wear zones.

Rehabilitation Process in 2016

1. IGS surveyed and mapped the problem areas.

2. IGS, Client, and the 3rd Party agreed on a repair procedure to include: removal of failed cladding, repeat inspection to determine severity of tube damage, mechanical tube repair, install IGS cladding installation.

3. IGS completed removal of the failed cladding (by means of grit blasting).

4. IGS, Client, and the 3rd party expert completed detailed NDT, visual, inspections to document and determine correct mechanical repair process in each location.

5. Client’s mechanical contractor began tube repair process. IGS supported inspection efforts throughout to ensure tubes were repaired to agreed standards.

6. Following complete sign-off of all repairs, IGS installed new fit-for-purpose cladding system in all repaired areas.

Lessons Learned

When Thermal Spray Cladding Systems are not properly specified, installed, or quality controlled, the consequences extend beyond poor performance — they can introduce entirely new issues. In this case, the end user experienced near-total failure of a competitor’s cladding material, leading to extensive and severe tube damage. The result was significant unplanned spending on mechanical repairs and additional outage time to restore the system.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.