Texas Tower/ VCFE Platformer Unblocked in Dominican Republic

TubeTech™ unblocked tubes with only 2m headroom and the top header in place.

A Vertical Combined Feed Exchanger (VCFE), also known as a Texas Tower, at a refinery on a Caribbean island was experiencing a significant drop in performance caused by blockages in the tubes. Texas Towers (VCFEs) are a vital piece of equipment as they cool down the platforming product against cold feed.

This type of heat exchanger has a very high heat duty. A 10% loss of heat duty due to fouling in the tubes translates to a financial loss of 1.5 million USD every year. Fouling can lead to blocked tubes, and this will eventually limit the design throughput. Such flow limitations lead to costly performance losses.

The Challenge

- This refinery satisfies most of the island’s car fuel needs. This dependency required the Texas Tower (VCFE) to be cleared of blockages and fouling on the tube and shell side to the highest possible standard, in the shortest amount of time.

- The Texas Tower (VCFE) was running at a significantly reduced performance, due to an unknown number of tubes that were blocked or severely restricted.

- The client estimated that approximately 12% of the 2,006 tubes were blocked.

- This estimate was based on the number of tubes that local contractors had been unable to unblock.

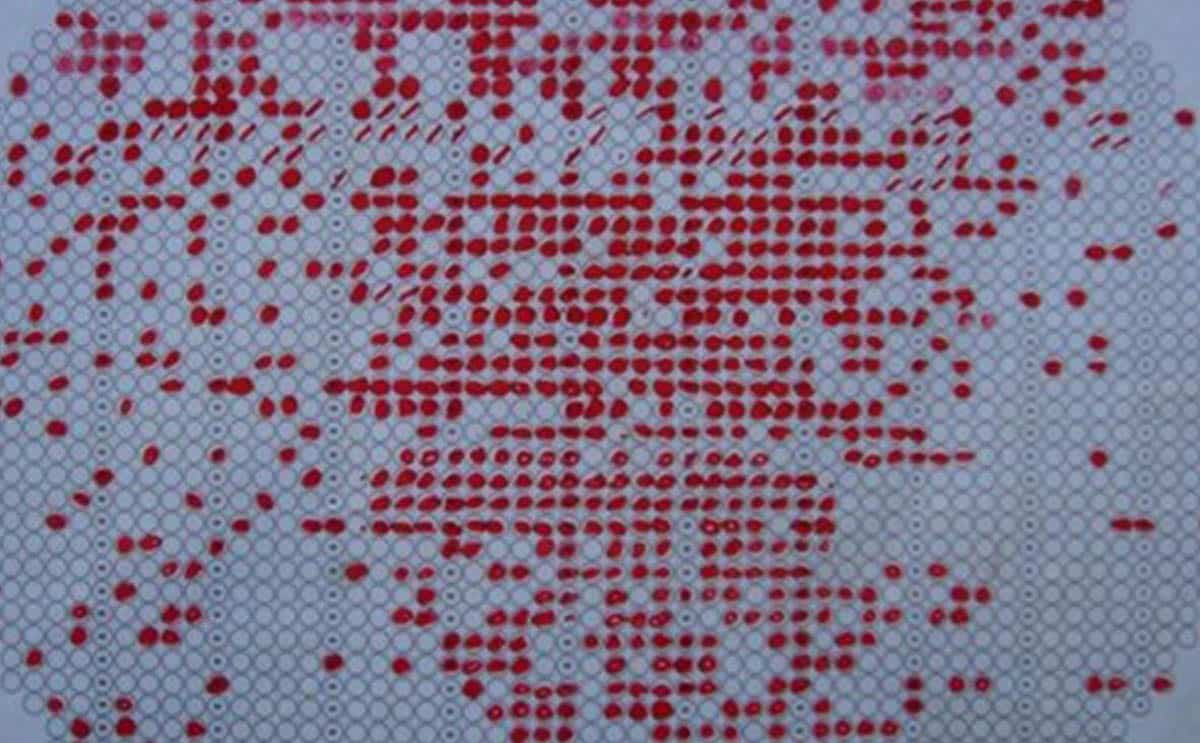

- Once the exchanger was opened, it was found that the number of blockages was closer to 50%.

- TubeTech™’s target was to unblock approximately 250 tubes in the time available to restore operation.

- A complication was that there was limited access to the top of the exchanger.

The Solution

- With the project located on a Caribbean island, careful planning and preparation were required to ensure adequate resources and equipment were available to complete the project without delays.

- Preparation included creating a full-scale mock-up of the bottom end of the exchanger, to ensure that safe man entry and access to the tube face would be possible.

- Equipment was packed with several different but complementary systems to ensure that all eventualities were accounted for.

- Equipment included a unique ‘pulsed jet’ system – specially developed to locate blockages where pulsed air/water is used to calculate the back pressure. This is excellent for locating and calculating the severity of blockages.

- Equipment also included a multi-lance system to deliver ultra-high-pressure water within the small tubes but with sufficient flexibility to clear blockages, backed up by the SafetyBoss, which prevents the lance head from exiting the tube while under pressure.

- Upon inspection, a variety of deposits were discovered such as hard mud, gum-like deposits, ferrous oxide scale, PCA and ammonium salts.

- With access to the top of the VCFE limited to an 18″/450mm flanged access port, drilling of the 300×24-metre-long tubes had to be carried out from below, which was a considerable challenge, and a world first.

- In just five days, TubeTech™ successfully completed the given scope of unblocking more than 300 tubes to allow the VCFE to be returned to production.

- TubeTech™ will return to clear the remaining 750 tubes in a similar time frame at the next turnaround.

Client Comment

“We planned the unblocking of the Texas Tower carefully to minimise downtime, but we did not expect the number of tubes that were found to be blocked when the exchanger was opened. Once support services had finished modifying the scaffolding and supplies to TubeTech™’s requirements, the fouling removal progress was very good. TubeTech™ showed great resourcefulness in adapting to the limited access situation. Our VCFE was unblocked and inspected to production standard without overrunning the shutdown period.”

Turnaround Coordinator

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.