Refractory Coating Achieves 4% Fuel Savings For An Ammonia Reformer

Application Situation

A Federal Government act for the industry requires asset owners and operators to identify opportunities for energy efficiency improvements and implement these projects.

Cetek has evaluated the ammonia reformer and projected fuel savings of 4% following the application of the ceramic refractory coating.

Ammonia Reformer Coating Application

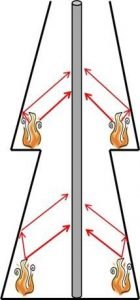

A 900tpd terrace wall single cell ammonia reformer furnace was operating with an elevated bridgewall and high stack temperature.

- Convection section : mixed feed, steam generation/superheat, BFW preheat

- Furnace had ¾ castable brick and ¼ ceramic fiber

- Scope: 6 Cetek crewmembers 3 days

- Cetek has evaluated the ammonia reformer and projected fuel savings of 4% following the application of the ceramic refractory coating

- Ceramic coating applied to all radiant refractory substrates

Cetek Ceramic Coating

Refractory Coating Benefits

The application of ceramic coatings onto refractory surfaces delivers a range of benefits, including:

- Increased production rate and/or fuel savings

- Minimized fouling of the convection section and the SCR catalysts

- Lower stack and bridgewall temperature, reduced NOx emissions

Coating Application Results

The project was completed on time and with no safety issues.

- Fuel savings: 360GJ/day – 4% fuel savings as projected

- Bridgewall temperature reduced by 50°C / 90°F

Ammonia Fired Heater Services

In addition to refractory coatings, IGS offers a range of services, which can be applied while the the ammonia fired heater is in operation:

• Hot Convection Cleaning • Hot Refractory Repair

• Hot Vacuum Service • Hot Inspection Service for fired heaters

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.