Cracker Quench Column Corrosion Stopped with IGS HVTS Cladding

The Problem

The erosion problem faced in the lower section of the quench column, arising from the impactful collision of high-velocity coke particles, turbulent forces, and elevated temperatures emanating from the feed, presented a critical need for strategic intervention. The urgency lay in ensuring the preservation of the structural integrity of the stainless steel-clad column. To address this multifaceted challenge, a comprehensive approach was imperative, one that not only mitigated the current erosion issues but also established a robust framework for long-term durability and operational sustainability.

The Solution

The resolution to the erosion predicament within the lower section of the quench column took shape through a transformative initiative led by IGS. This innovative approach involved the integration of HVTS cladding into the internal shell of the column, marking a significant leap in technology application. This pioneering solution adeptly confronts erosive challenges stemming from high-velocity coke particles, turbulence, and elevated temperatures. HVTS cladding not only addresses these challenges but also delivers substantial and lasting reinforcement to the stainless steel cladding, ensuring the enduring integrity and longevity of the quench column.

Key Benefits

The Implementation of HVTS cladding by IGS marked a revolutionary shift in the approach to address erosion issues within the quench column. This cutting-edge technology delivered a host of key benefits:

- Enhanced Erosion Resistance

- Observation of Structural Integrity

- Increased Operational Reliability

- Cost Saving

- Sustainable Performance

- Pioneering Technological Advancement

Technical Solution

Click here

This case study highlights how IGS employed High Velocity Thermal Spray (HVTS) cladding technology to address erosion issues in the quench column. The project, covering an area of 45 square meters, underscores IGS’s dedication to safety, quality, and the successful completion of projects in the realm of industrial infrastructure maintenance and enhancement.

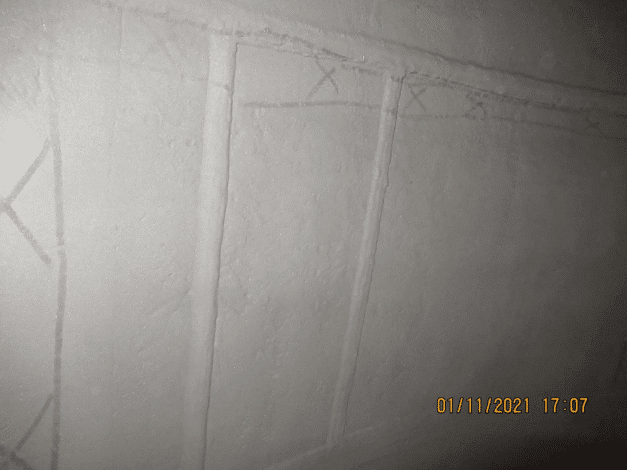

Completed HVTS of IGS to weld seams of shell

IGS successfully executed the High Velocity Thermal Spray (HVTS) process using IGS 5000 series cladding to protect and enhance the weld seams of the shell. This comprehensive application ensures the robust reinforcement of the weld seams, leveraging the advanced capabilities of IGS HVTS for superior performance and longevity.

The HVTS application utilizing IGS HVTS has been successfully completed, specifically focusing on the intersection points between the shell and baffle plate. This meticulous application guarantees complete coverage of all weld seams, showcasing the efficacy of IGS HVTS in providing comprehensive protection and reinforcement for enhanced durability at critical junctures within the structure.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.