Hot Convection Cleaning Reinstated Overall Furnace Efficiency Without Shutdown

Cleaning Fired Heaters Online

Cetek’s Hot Convection Cleaning (HCC) service helped the client to remove severe convection section tube fouling during furnace operation without a shutdown and loss in production. In addition, IGS created engineered access ports to facilitate the cleaning process and for future access. Cetek online convection tube cleaning is efficient, environmentally friendly, and safe for removing years of fouling without disrupting production. The total fuel efficiency increase was 2%.

Increasing CCR Fuel Efficiency

The object of hot convection cleaning was the CCR Platforming heaters where previously Cetek High Emissivity Tube Coatings were applied. The convection section was dedicated not only to steam generation but to the stabilization column heat input as well. The prime target for the client was to increase total fuel efficiency by increasing process duty to a greater extent rather than increasing steam duty.

Project Execution: Hot Convection Cleaning

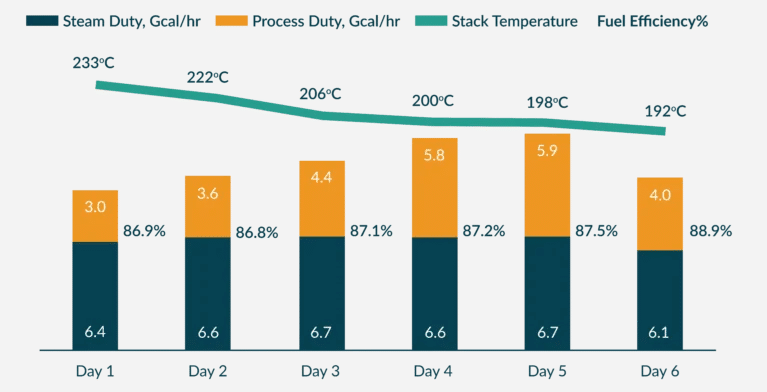

A critical path during February 2022 lasted 6 days. The Cetek crew partially removed the outer shell and related refractory, thus, 29 rectangular reusable access ports were created to gain access while the unit was operating. No change to operation was needed as long as a draft was kept constant. Cetek installed a refractory cast plug and plate affixed to the shell after the execution. The operating parameters were collected daily to track the performance of the heater system during the cleaning process. During days 1 and 6 excess air % was pretty much the same allowing us to make a reasonable comparison before and after project execution.

HCC Project Results

The previously calculated benefit based on 40% of the clean surface was exceeded. The application of HCC resulted in:

- 41 °C drop from high stack temperature almost to the design value.

- 2% overall fuel efficiency gain.

- 25% gain in process duty.

- Rapid payback.

- Availability of reusable access ports in the convection section for future maintenance.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.