Heat Exchangers (Crude Train) Restored to Design Parameters at a Refinery

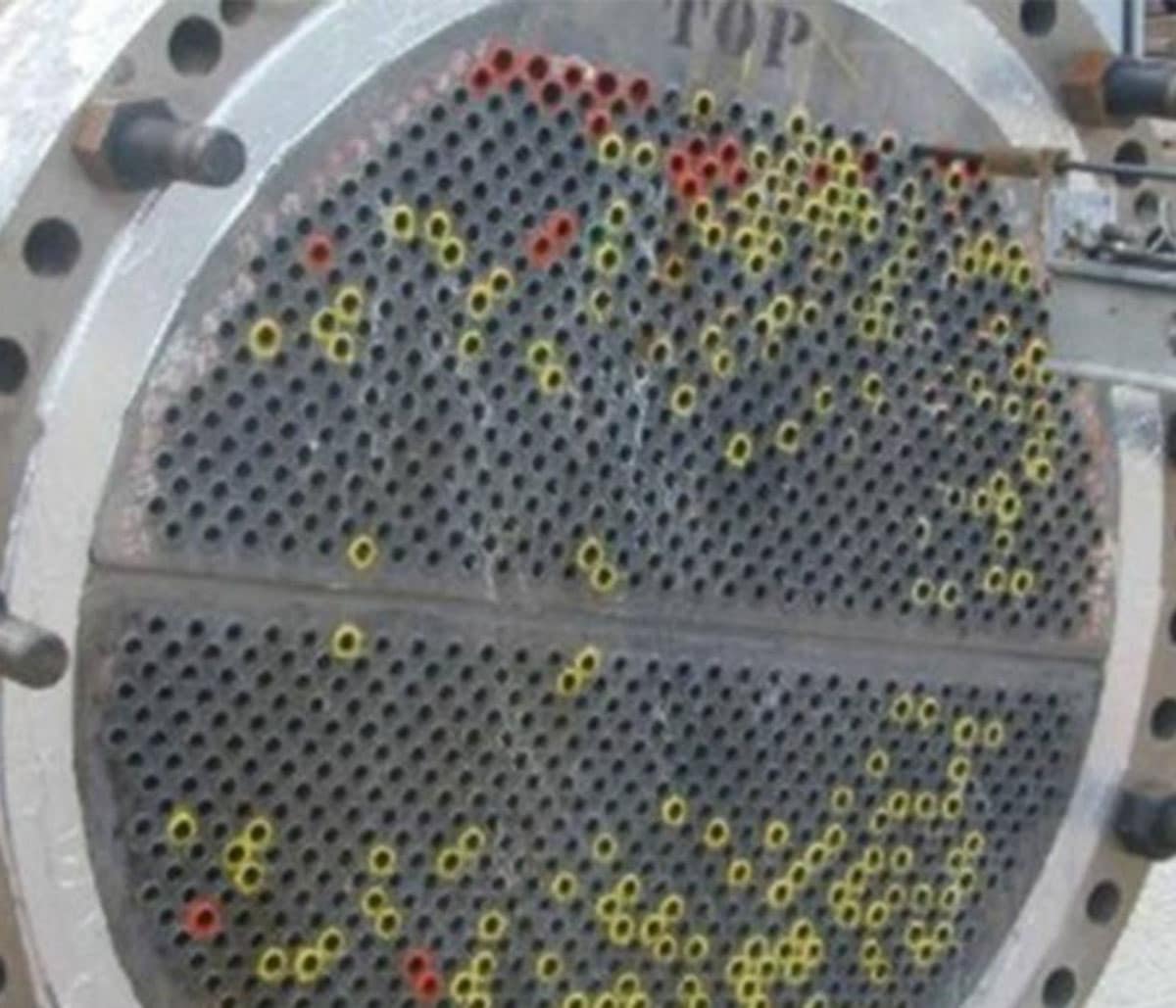

U-Tube (Hairpin) Heat Exchanger Blockage

An Arabian gas liquefaction company had a problem with their titanium U-tube (hairpin) heat exchanger blocked by calcium carbonate and tenacious silicate deposits. IGS TubeTech™ removed the hard deposits from within the fragile tubes and restored heat transfer efficiency.

Titanium Heat Exchanger U-Tubes Blocked by Hard Deposits

- Titanium heat exchanger tubes typically have a long operational lifespan; however, with time they can be blocked with fouling.

- The U-Tube exchanger was heavily blocked around the hairpins with calcium carbonate and tenacious silicate deposits which had contributed to a loss of heat transfer efficiency.

- TubeTech™ was contracted because the heat exchanger had very long tubes and our team has a reputation for being successful with challenging heat exchanger restoration projects.

- Titanium tubes, while having excellent heat transfer properties, are thin and soft and require a higher level of care to prevent damage during cleaning.

Removing Hard Deposits from Hairpin Titanium Heat Exchanger Tubes

- A multi-phase heat exchanger restoration approach was devised which started with a low-volume 60,000 PSI (4,000 BAR) water jetting system utilising WysperDrill, intelligent metal lances which conformed to the shape of the tubes while drilling and jetting simultaneously.

- As acid-type chemicals are not recommended on titanium, a biodegradable wash was used to remove traces of scale from the tube walls once a bore was created.

- A miniature rotating darTT, unique to TubeTech™, was fired around the bend before a video probe returned a 3D image to confirm no damage to interior bores.

- Careful use of bespoke jets and turbines and the lack of aggressive acids meant the titanium suffered no damage and was pristinely polished.

TubeTech™ Comment

“The hairpins were solidly blocked. This level of blockage and hardness factor has always previously meant a re-tube or full replacement. We had to take great care because the heat exchanger was titanium, perhaps the only one of its type that has been restored in this manner.”

Due to bespoke Intellectual Property being deployed, TubeTech™ is happy to demonstrate and discuss the unique U-tube heat exchanger cleaning process if further information is required.

Client Comment

A spokesperson for the client said:

“We were very satisfied with the standard achieved. We had tried drilling, high-pressure jetting at 1,000BAR and various chemicals with no joy. Our objective was to unblock 5% of tubes to reach satisfactory performance.

TubeTech™ achieved 7% in a short time and promised to attain 95%-plus if required. This avoided a full and expensive retube costing at least $250,000. We will have no hesitation in calling in TubeTech™ again.”

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.

Contact us