Fired Heater Shutdown Prevented with Hot Refractory Repair

This U.S. Refinery is a downstream energy company with assets in petroleum refining, logistics, convenience stores, asphalt, and renewables with a capacity of less than 150,000 barrels per day. The Refinery produces types of gasolines, distillates, and propane products.

Problem

A refinery in the U.S. has discovered serious refractory integrity concerns on their CCR unit. The refractory ceramic fiber was missing. As a result, the outer steel shell was damaged due to the exposure to the high temperatures in multiple areas of the roof and sidewall.

Solution

IGS Hot-tek team was invited to repair the damaged refractory roof areas, using Hot-tek Hot Refractory Repair Services, while the unit was running at full capacity. All quoted areas of the roof were repaired, along with two additional damaged areas, discovered during the project.

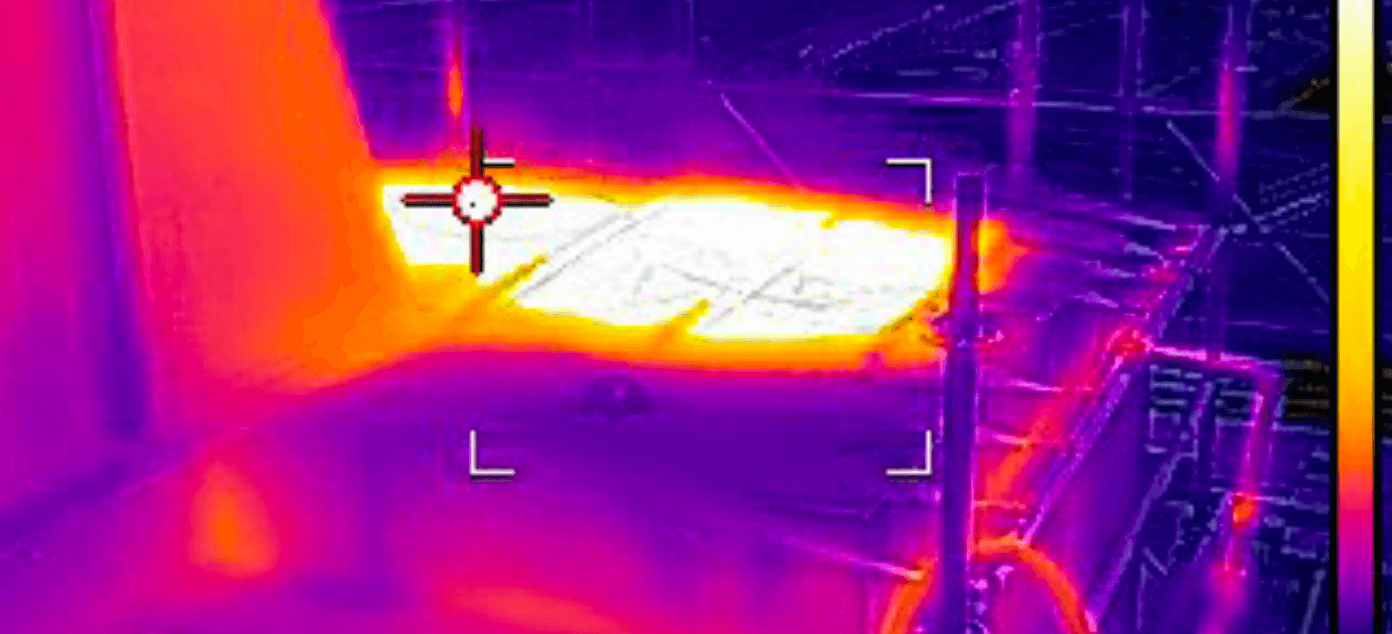

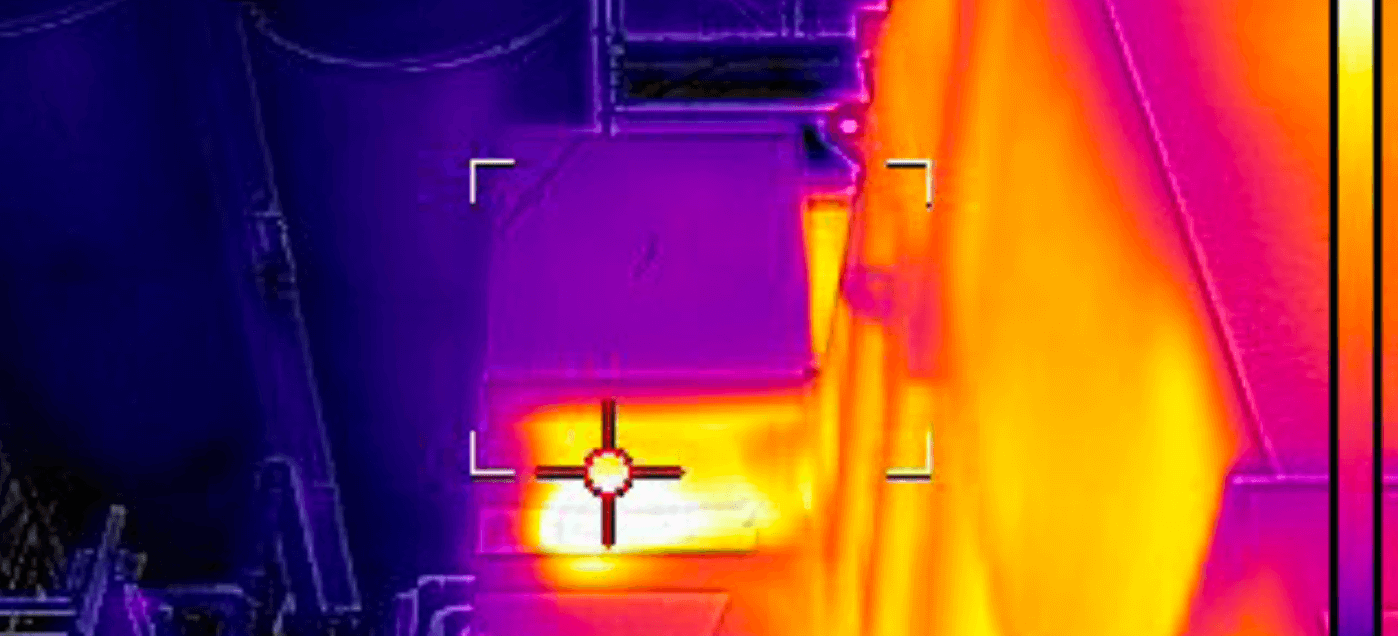

Refinery Furnace Infrared Images Reveal Problem Areas

The Hot-tek team took infrared images of the hot spots on the CCR fired heater roof during the pre-job meeting.

Temperatures of over 1500°F/815°C were being reached at the bridge wall, relatively high for a CCR fired heater. Material selection utilized in the previous repairs was not sufficient for these elevated bridge wall temperatures.

Imminent Shutdown Prevention

This busy refinery was looking at a permanent solution to this problem while avoiding a shutdown, which would have severe consequences to their revenues and operations.

IGS Hot-tek team repaired the damaged refractory roof areas, using Hot-tek Hot Refractory Repair Services, while the unit was running at full capacity. All quoted areas of the roof were repaired, along with two additional damaged areas that were discovered during the repair.

Damaged areas were repaired using two techniques; IGS Hot-tek’s unique basket style repair and the larger module repair. The larger damaged roof areas were cut into sections and removed. Then prefabricated modules were installed in place. Higher alloy plate and hardware along with higher temperature ceramic fiber created a long-term repair solution for the refinery.

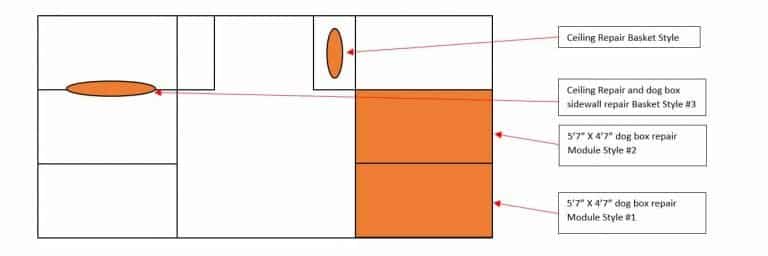

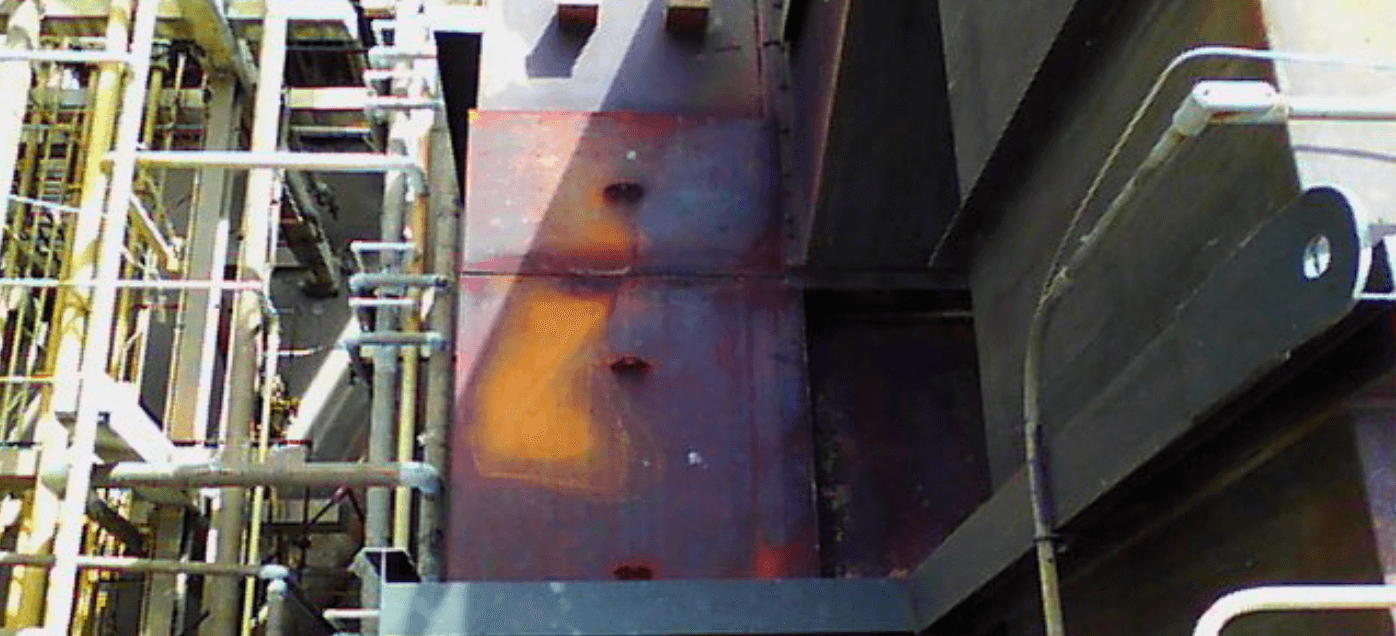

Hot-tek Repair Areas

Damaged areas were repaired using two techniques; IGS Hot-tek’s unique basket style repair and the larger module repair. The larger damaged roof areas were cut into sections and removed. Then prefabricated modules were installed in place. Higher alloy plate and hardware along with higher temperature ceramic fiber created a long-term repair solution for the refinery.

Hot-tek #1 & #2 Repair Area

Repaired using Hot-tek Module Style on the ceiling of the installed dog boxes.

#1 & #2 Repair Area – IRR Image

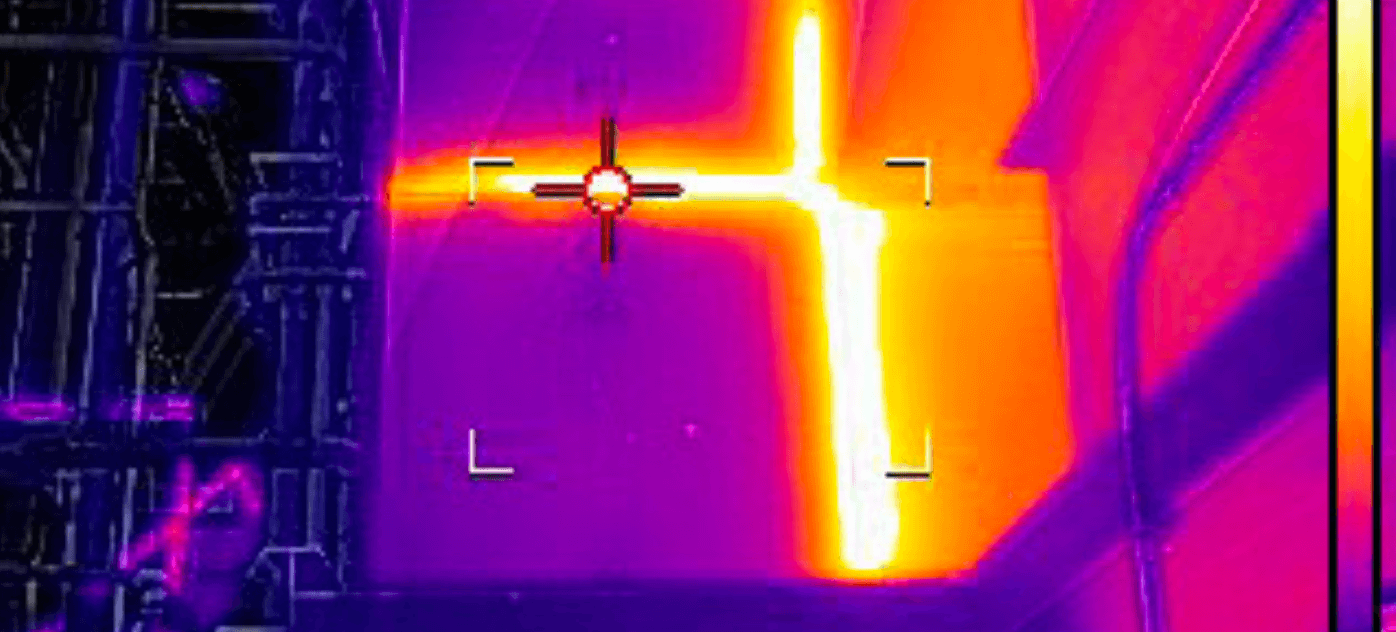

Hot-tek #3 Repair Area

Repair performed utilizing the Hot-tek Basket Style Repair on the existing ceiling.

#3 Repair Area – IRR Image

Hot-tek #4 Repair Area

Repair performed utilizing Hot-tek Basket Style Repair on the side of the Dog Box and existing ceiling.

#4 Repair Area – IRR Image

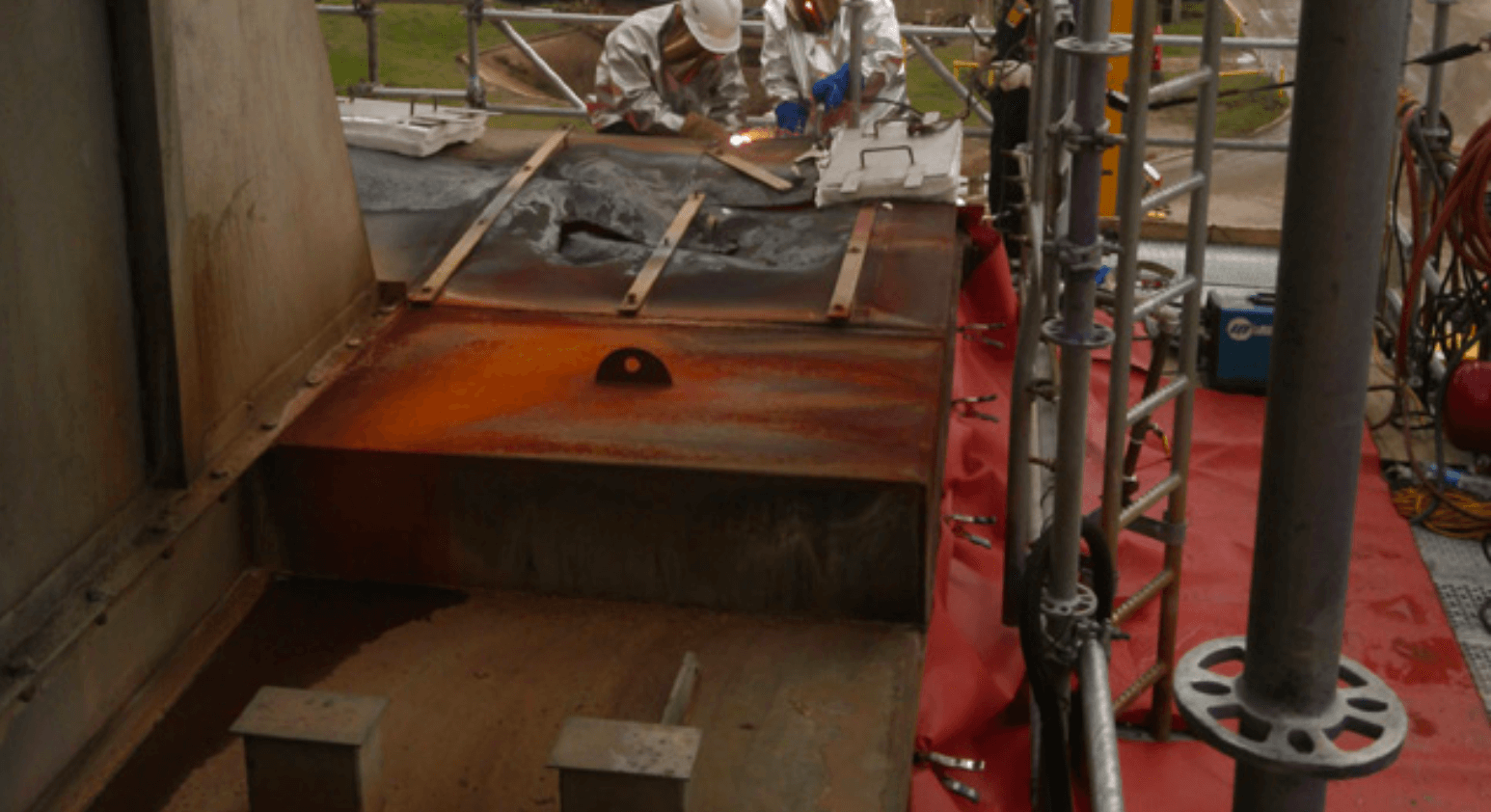

Step-by-Step Hot-tek Repair Solution

1. Cutting Tiles, Leaving Area for Support

We cut the first tile using a plasma cutter and removed it from the furnace ceiling. Approximately 1”-2” area of the original furnace shell we left for support for the new Hot-tek Module. After installing the module temporarily, our Hot-tek team then moves to the next tile.

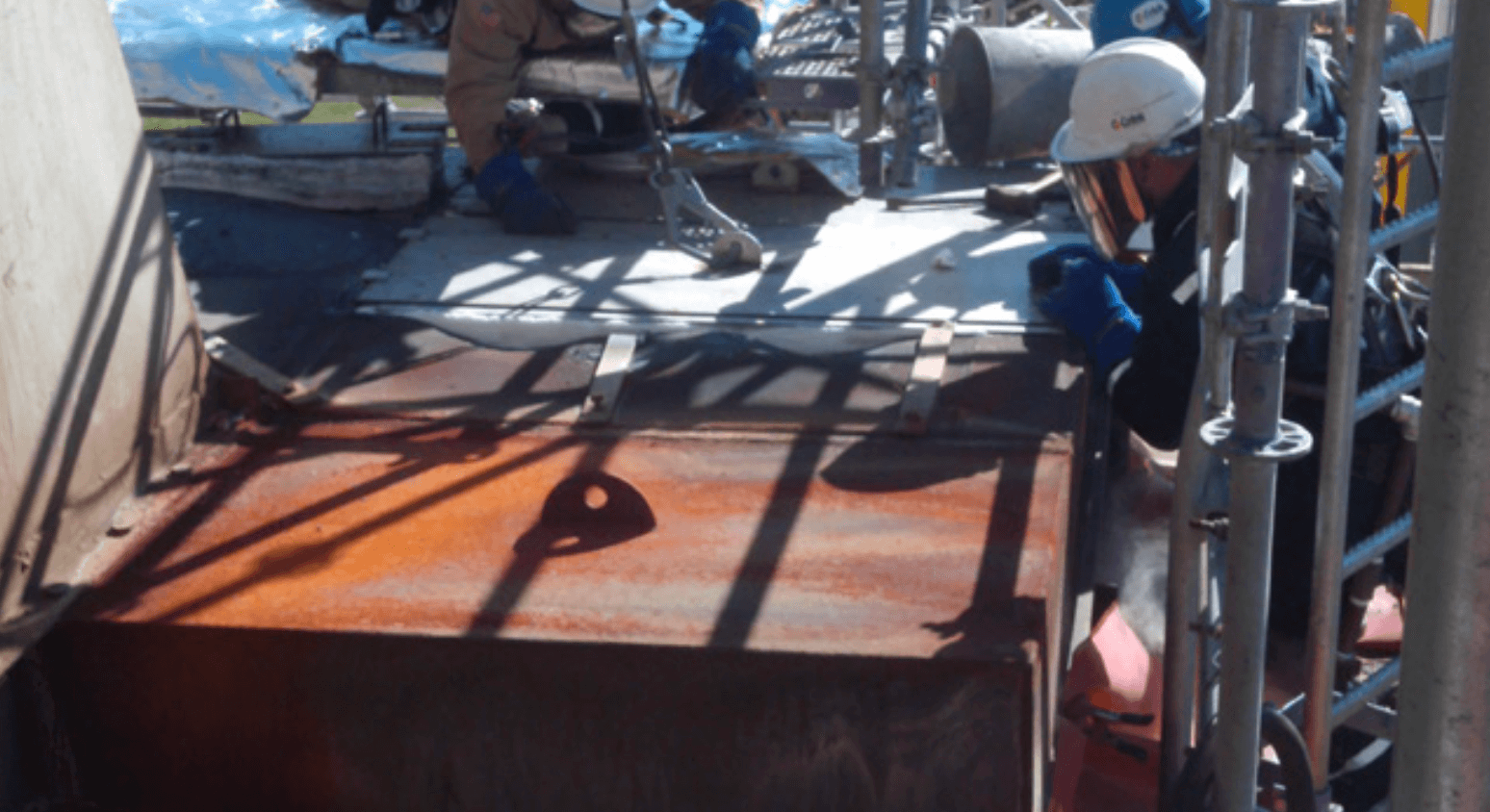

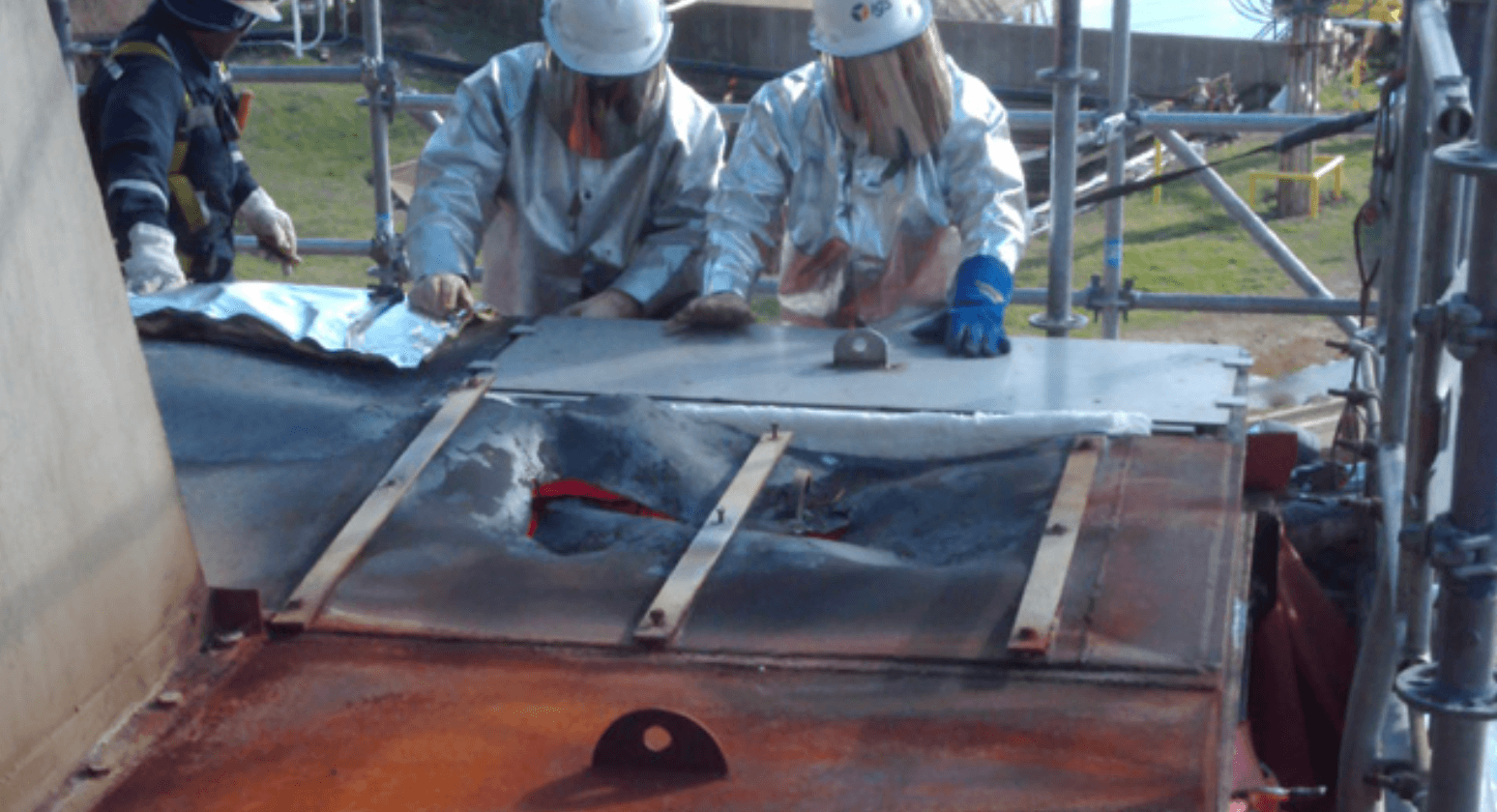

2. Installing Prefabricated Hot-tek Module

Our team installed a prefabricated Hot-tek module and tack welded it into the place.

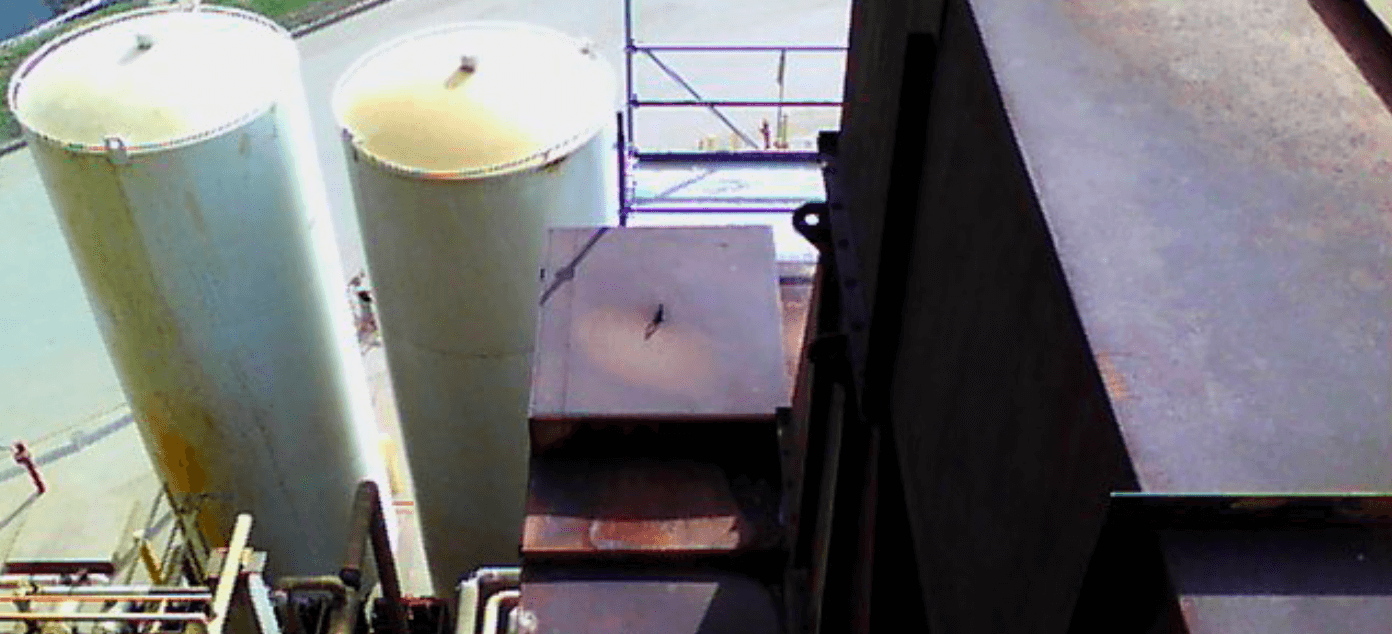

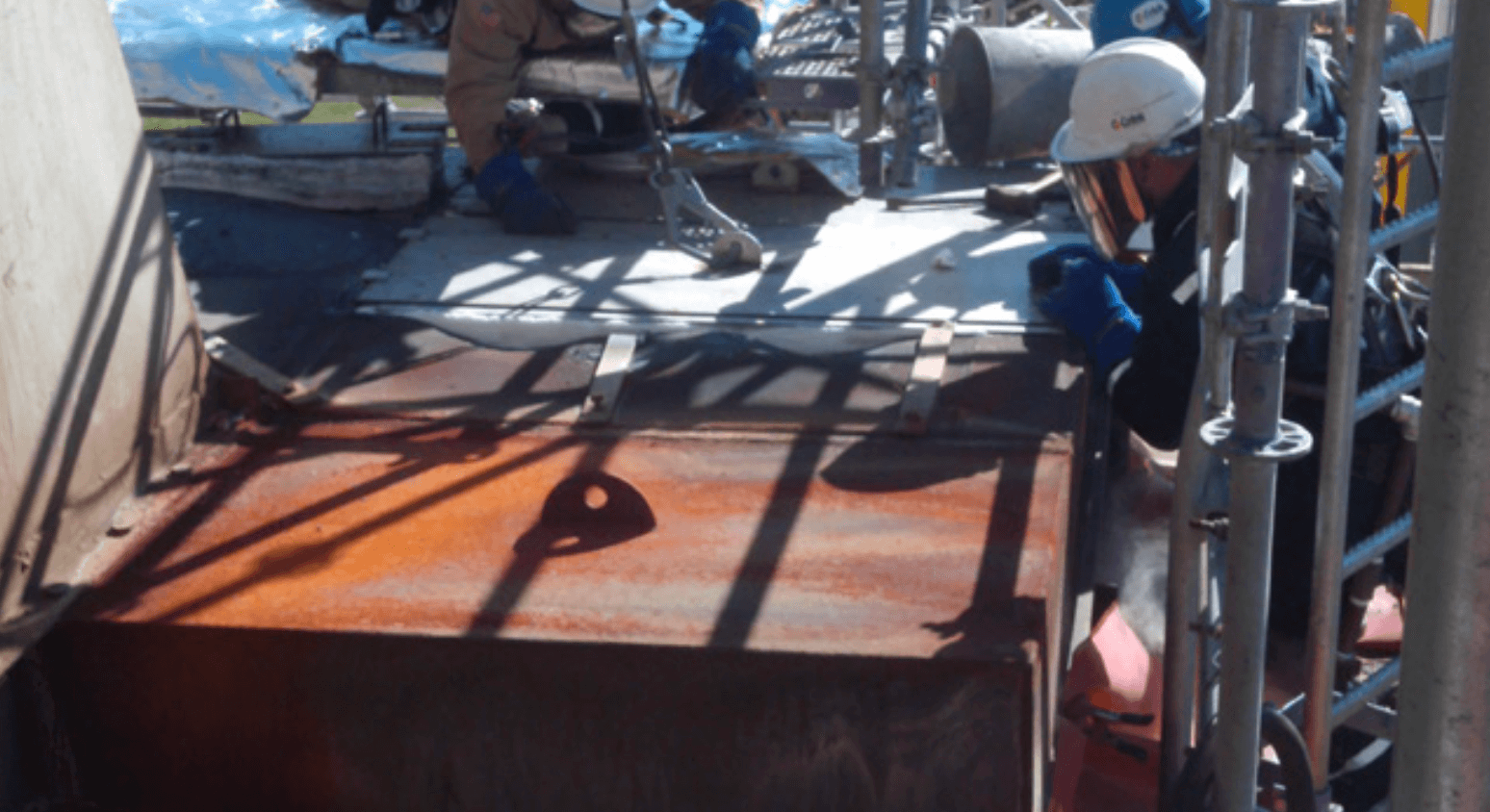

3. Large Module Installed in Another Section

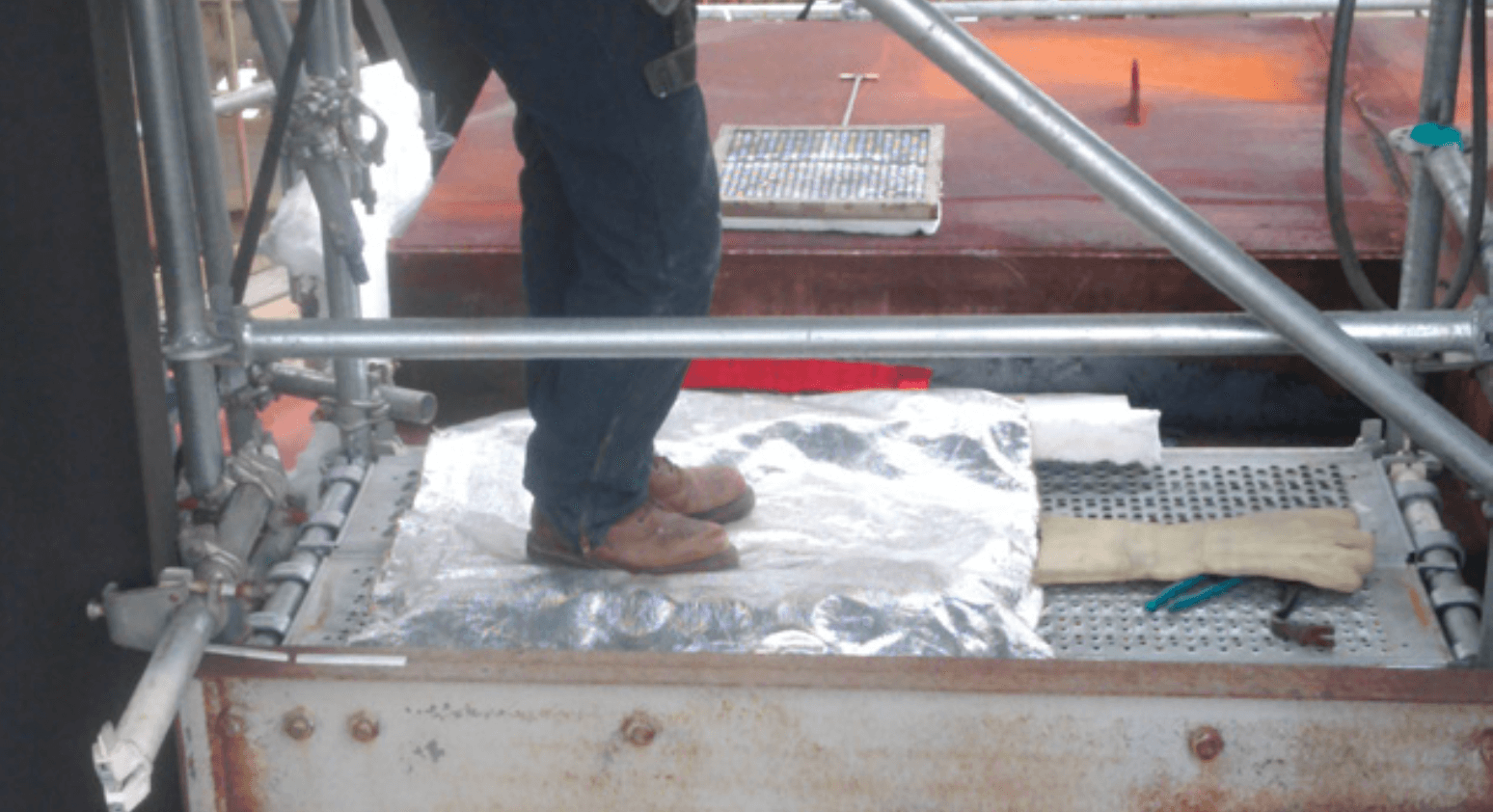

The installation of the large module was completed in the next roof section. The module and technician were tethered for safety.

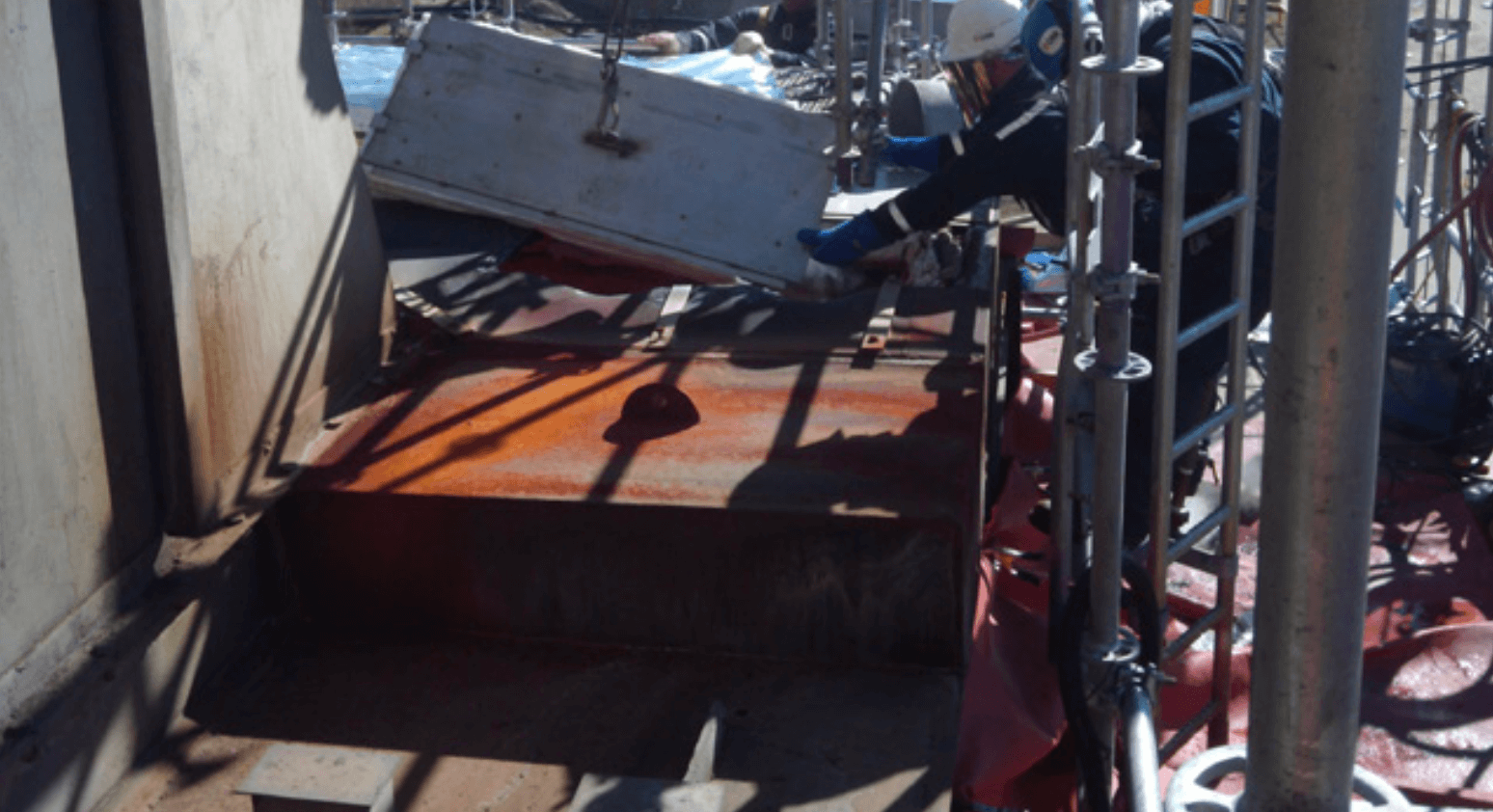

4. Module Fitted and Welded in Place

We fitted and fully welded the module in place with an alloy rod for dissimilar metal welding.

5. Hot-Tek Basket Solution

We repaired a large damaged roof area with 16” square alloy Hot-tek baskets. We welded these baskets together to form the new “ceiling” of the roof.

6. Pouring New Refractory

We laid pourable/pumpable refractory into the large opening. After curing, the surface becomes cool to the touch. Once cool, we welded an alloy plate over the refractory.

7. Cut to Verify Obstructions

An initial cut was made in the roof to verify any obstructions.

8. Slit Made for Hot-tek Basket Installation

After verification, a larger slit was made into the roof for the installation of the baskets.

9. Baskets or Plates Placed in the Opening

Securing any loose roof refractory and welded in place before backfilling with pumpable refractory.

10. Completing the Repair

The plasma cut opening was extended while the unit was running. Vertical surfaces can also be repaired utilizing a similar technique.

11. Fiber Lined Baskets Installed

After the cut was made, fiber lined baskets were installed, cooling the surface area immediately.

12. Result

IGS Hot-tek solution was performed within the agreed schedule over 8 days. Refinery continued operations in full capacity, completely unaffected by the repairs taking place.

A shutdown would have cost the refinery millions in lost production.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.