From Welding to Predictable CFB SMARTGard Boiler Maintenance since 2003

A power plant in Texas with 350MW capacity has two CFB boilers. The boilers were designed by a South Korean boiler manufacturer and have gone into service in 1990 and 1991. The boilers burn lignite fuel and the fluidized bed technology utilizes limestone injection to reduce nitrogen oxide and sulfur dioxide emissions.

Problem

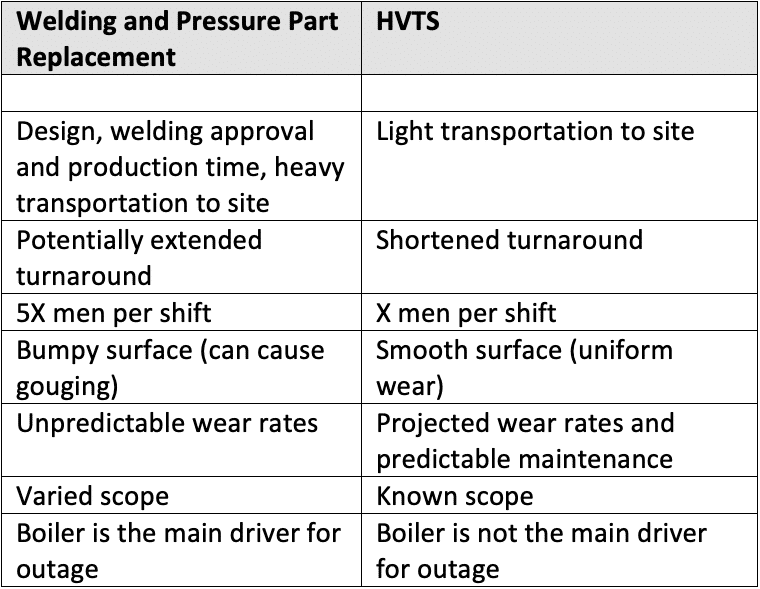

Tube metal erosion in the areas adjacent to the refractory. Repeated welding repairs led to unpredictable wear rates and the risks of tube leaks.

Solution

IGS’ SMARTGard® service applied HVTS alloy cladding on-site since 2003 to stop tube metal wastage and provide a predictable annual maintenance spend.

The Challenge

Pressure parts, including the lower furnace zone refractory interface and the corners of the boiler suffered from erosion leading to tube metal thinning. The plant was using carbon steel weld buildup on their tubes at the refractory interface as an annual maintenance practice. Carbon steel buildup is a constant repair item as the bed ash is harder than the carbon steel weld buildup.

Weld Build Up

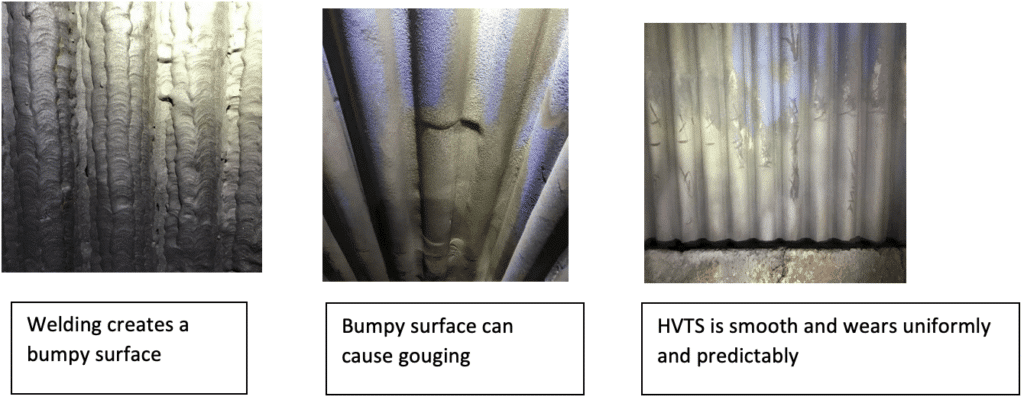

Hard surfacing also creates irregular bumpy patterns that set up little locations for eddy currents. These areas can experience gouging leading to severe rapid metal loss.

Comment

Paul Strauss, IGS Boiler Maintenance SME, said: “The plant is extremely satisfied with IGS as we get the job done on time and within budget with the highest quality. Our ability to match the cladding thickness with erosion rates has been a key factor to our success, as we are able to build the cladding up to 50 mils in the worst areas of the boilers.” The latest capacity factor for the plant is 98.7%.

Transition from Welding to SMARTGard HVTS

Large mechanical repair process during each outage can shift to a less labour-intensive thermal spray application.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.