Furnace Emergency Shutdown Prevented! Hot Spot Repair Saves Refinery $15 Million

Fired Heater Emergency

Fired Heater Emergency required immediate attention. The refinery saved $15 million by avoiding a forced shutdown. The shutdown would have cost the plant more than $1 million per day in lost production to repair the hot spots in their fired heater. Conventional repair would have taken 2+ weeks to complete, considering all shutdown and start-up procedures.

CCR Heater Emergency – Roof Anchor Failures

A refinery faced a direct fired heater emergency. Multiple adjacent anchor failures in the roof of the continuous catalytic reformer (CCR) heater caused the ceramic fiber refractory lining to fall to the floor, allowing hot flue gas to reach the exposed shell, oxidizing the steel & exposing the centre beam, which could jeopardize the structural integrity of the heaters.

Emergency Response to Furnace Emergency

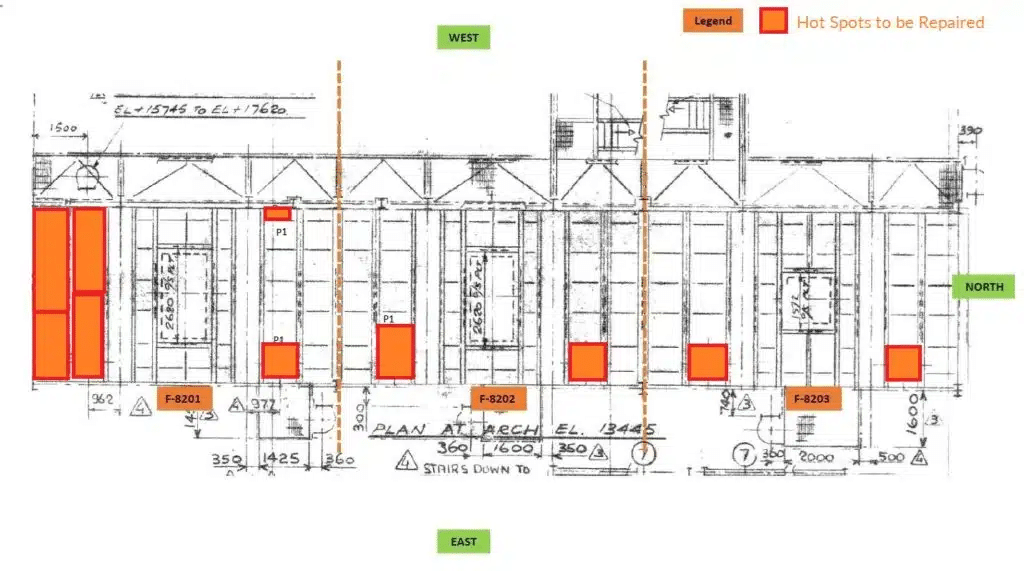

Integrated Global Services (IGS) utilized their Hot-tek hot refractory repair solution online without disrupting daily operations. The initial scope of work consisted of repairing three (3) hot spots on the south end of the roof of the heaters. Once the maintenance team witnessed IGS’ expertise and safety standards, they immediately asked for the extension of the repair scope to include additional hot spots within furnace 1 as well as adjoining furnaces.

Safety

Health and safety are primary concerns at IGS, and we firmly believe that continued emphasis on our active, behavior-based safety program will continue to provide a safe, healthy workplace for our personnel and those around them.

Especially in the cases of heater emergency, the following procedures and practices are vital to maintain a safe working environment on this project. Daily Toolbox Talks were held at the beginning of every shift, Daily Safety Observation Forms were completed by IGS employees. IGS conducted a daily walkdown of the unit to ensure all safeguards and lockouts were in place and not tampered with and the IGS Job Safety Audit (JSA) prior to and after set-up for inspecting and ensuring safety standards were met onsite.

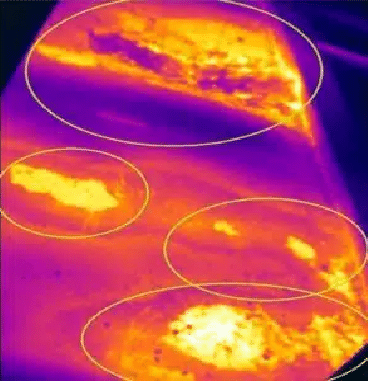

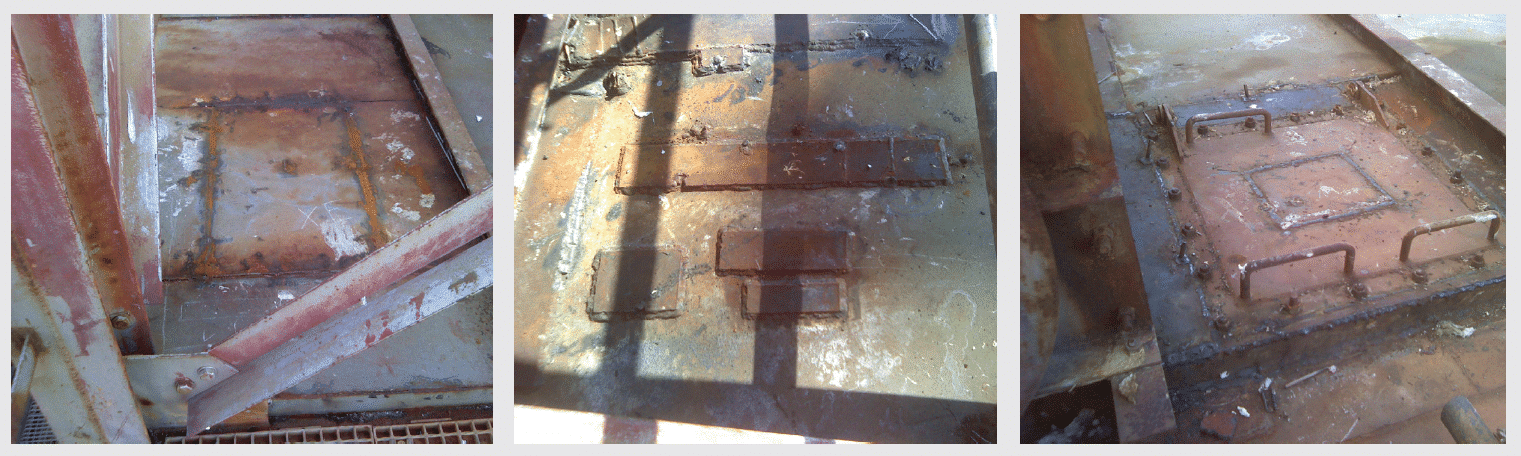

Completed Hot Spot Repair

The internal hot spots on the unit were extreme with temperatures upwards of 7000C /13000F. In several areas there were large holes in the casing and significant sections of the ceramic fiber could be seen hanging where it had detached from the anchors. During the project nearly 100 baskets/plates were utilized to secure the shell and more than 200ft2 were included in the repaired surface area. The key steps included identifying each location for the potential repair, removal of failed shell, cutting proper access holes, installing internal walls, refilling with pumpable fiber, reinstalling outer shell and inspecting for hot spots on same.

Heater Emergency Repair Results

The Hot Refractory Repair (HRR) Work specifications, Method Statement, JSA/JHA and Completion Certificate were reviewed by client’s inspector and then accepted by the client on final work sign-off. The project was completed without a safety incident and in compliance with the projected timeline. IGS team successfully eliminated and/or decreased the extreme temperatures along with repairing several breaches in the casing. This scope halted further delamination of the ceramic fiber by reinstalling refractory and proper supports eliminating an unplanned shut-down. These types of IGS repairs provide the client with many years of trouble-free performance. They plan to monitor the repairs by taking periodic IR images of the shell temperature and will inspect the repairs during the next planned TA.

Testimonial

“I wanted to take a moment to express my sincere gratitude for the great job your team did on our furnace roof while the furnace was still online. We were impressed by your team’s level of skill, precision, and professionalism. The repair was completed successfully without any disruptions to our production schedule, which is a testament to your team’s hard work and dedication. I also appreciate your patience and willingness to answer our questions and concerns throughout the process. Your guidance was invaluable.”

– Head of Maintenance, Refinery

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.