Protected: PRB and Lignite-Fired Boilers Corrosion

High Ash Content in the Boilers

Lignite is also known around the world as brown coal. PRB is sub-bituminous coal mined from the Powder River Basin in Wyoming.

Generic heating values are as follows: Lignite- 7,000 Btu, PRB- 8,150 Btu. Both heating values are relatively low and result in high ash formation in the boiler.

Causes of Corrosion

Water Cannons

Water cannon usage can create cracks on low grade waterwalls over time. Circumferential cracks are formed by oxide wedging.

Soot blowers

Soot blowers, usually steam, are designed to clean slag or fouling off the tubes. These systems are activated manually or automatically. The force of the soot blower will remove slag from the tube, which causes a slight local thermal shock, releasing slag and iron oxide scale. Each time the scale is removed from the tube, new scale grows. The soot blower is essentially causing erosion and corrosion damage to the tube. On occasion, especially on the nose arch retractable lances, the steam soot blowers will not drain properly and inject condensation onto the tube, amplifying the damage.

Reheater Pendants

Reheater Pendants are placed in close proximity to one another to capture as much heat as possible. When the tubes start bridging ash across the fronts of the elements, gas velocity picks up across the system, increasing wear.

As ash builds, velocity increases, leading to the wear on the fronts and the tubes. To compound this problem, sootblower lances travel across the fronts of these elements.

Lower Slopes

The lower slopes in the Lignite and PRB boilers will suffer from sliding abrasion. The ash consists of a heavy loading of Alumina and Silica, which abrade away the tubes.

Eliminating the Problem

When a tube is protected with the IGS HVTS® cladding, there is no oxide growth on the fireside surface of the carbon steel tube, thus preventing the creation of the oxide wedge.

IGS HVTS® Cladding will prevent further tube wastage due to:

1) the material will prevent scale growth

2) HVTS® cladding is 15X more erosion resistant compared to carbon steel.

The HVTS® can be installed on any tube, including carbon steel, stainless, or Inconel composites. This results in a life extension of the tube, preventing immediate tube replacement. HVTS® also prevents the use of tube shields. HVTS® cladding is 15X more erosion resistant compared to carbon steel, >10X over stainless steel. [figure 3]compared to carbon steel. [figure 2]

The HVTS® cladding is 15X more erosion resistant compared to the carbon steel slope tubes.

Case Study

Lignite

Two 750 MW lignite-fired supercritical boilers in Texas utilize IGS HVTS® Cladding to protect the Coutant slopes from abrasion and waterwalls – from circumferential cracking caused by CATF, due to watercannon usage.

The boilers have been protected with IGS HVTS® cladding since the units were commissioned in 2010 and 2011 respectively.

PRB

One 922 MW PRB-fired supercritical spiral wound boiler in Iowa utilized IGS HVTS® Cladding to prevent further waterwall cracking due to watercannon activity.

Return on Investment

Both plants, between all 3 boilers, saved a tremendous amount of money by upgrading the alloy of their existing tubes with IGS HVTS® comparing to wholesale pressure part replacement.

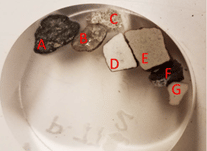

Mounted Ash

SiO2 and Al2O3

IGS HVTS®

The IGS HVTS® claddings have been proven around the world to address severe corrosion and erosion problems in utility boilers, resulting in significant cost savings by preventing tube replacement and increased unit availability & reliability.

We have seen several of the PRB units in the Western US recently convert to Low NOx burners which is resulting in fireside corrosion, caused by reducing atmosphere sulfidation. There are also a few units injecting calcium bromide in with their coal for mercury reduction. This new corrosion in the boiler tubes is adding another dynamic to the tube loss.

Other units have been swinging load with wind, which causes another set of problems such as CATF cracking and changes in the slagging of pendants. If the plant operator has just discovered the damage and is being reactive, or if we are looking at a proactive long-term plan, the IGS HVTS® is the way to go when comparing it to welding rework or panel replacement.

By doing the same thing over and over, you should expect the same results. The IGS HVTS® cladding is an alloy upgrade to your existing tubes.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.