IGS has extensive knowledge and experience with utilizing air cannon technology to solve a wide variety of buildup accumulation problems in industrial equipment.

Through over 50 years of combined experience, we have been able to continually improve on and develop new technologies to more effectively serve the Power Generation and similar markets at a lower cost of ownership to our customers.

IGS Big Blue Air Cannon design maximizes energy and yields the greatest cleaning force in the Industry today, blasting away the buildup and blockage. Let the Power of Blue work for you!

Why install air cannons where your maintenance team can’t perform their job or in hot environments, leading to poor reliability. Protect your maintenance crew and your air cannon! IGS is the Industry leader in designing systems that eliminate these issues. Remote mounting equals greater reliability.

Simple piston assembly offers a more robust design with less moving parts that resist corrosion and wear better than traditional systems, resulting in higher reliability and reduced maintenance costs. Eliminate the springs, which cause frequent failure. Use standard off-the-shelf replacement parts instead of being held hostage for replacement parts from the OEM. Lower the costs with IGS off-the-shelf air cannon replacement parts.

IGS offers a wide range of air cannon nozzle designs engineered for their specific application. Nozzles that improve the cleaning force to nozzles designed to reduce the number of air cannons required to perform the cleaning job.

Adjustable force air cannon delivers the cleaning force that maximizes cleaning results. The combination and control of peak force, the air volume, and discharge time results in far better cleaning.

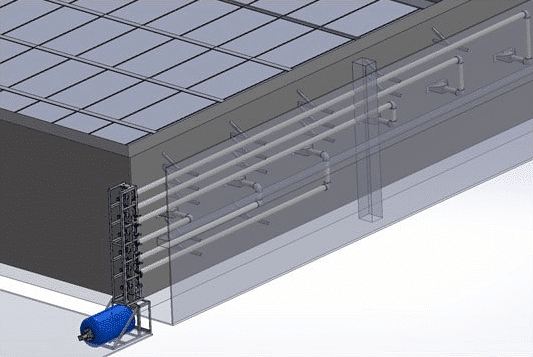

The IGS 300L Blue and BIG BLUE air cannon mounting configurations provide many benefits over a standard air cannon installation for SCRs, dry scrubbers, and silos.

It is less expensive to install and purchase and provides more powerful, effective cleaning! It also allows for remote mounting configurations, which save platform space and can reduce or eliminate the need for platform modifications.

It also has fewer moving parts, creating a simpler system requiring less maintenance and fewer spare parts to be kept in inventory.

The IGS multiplier technology allows for a very flexible system installation, available in various configurations to suit the system’s needs and spatial requirements of the tempering Air Ducts, LPA Screens, and ESP Distribution Plates.

IGS has focused extensively in designing and testing remote mounted applications, made possible using the IGS multiplier systems. Remote mounted systems allow for installations where access or space is limited.

Remote mounting can eliminate the need for expensive platforms or other extensive system modifications. All components requiring maintenance are installed in a location with easy access, away from the vessel wall itself.

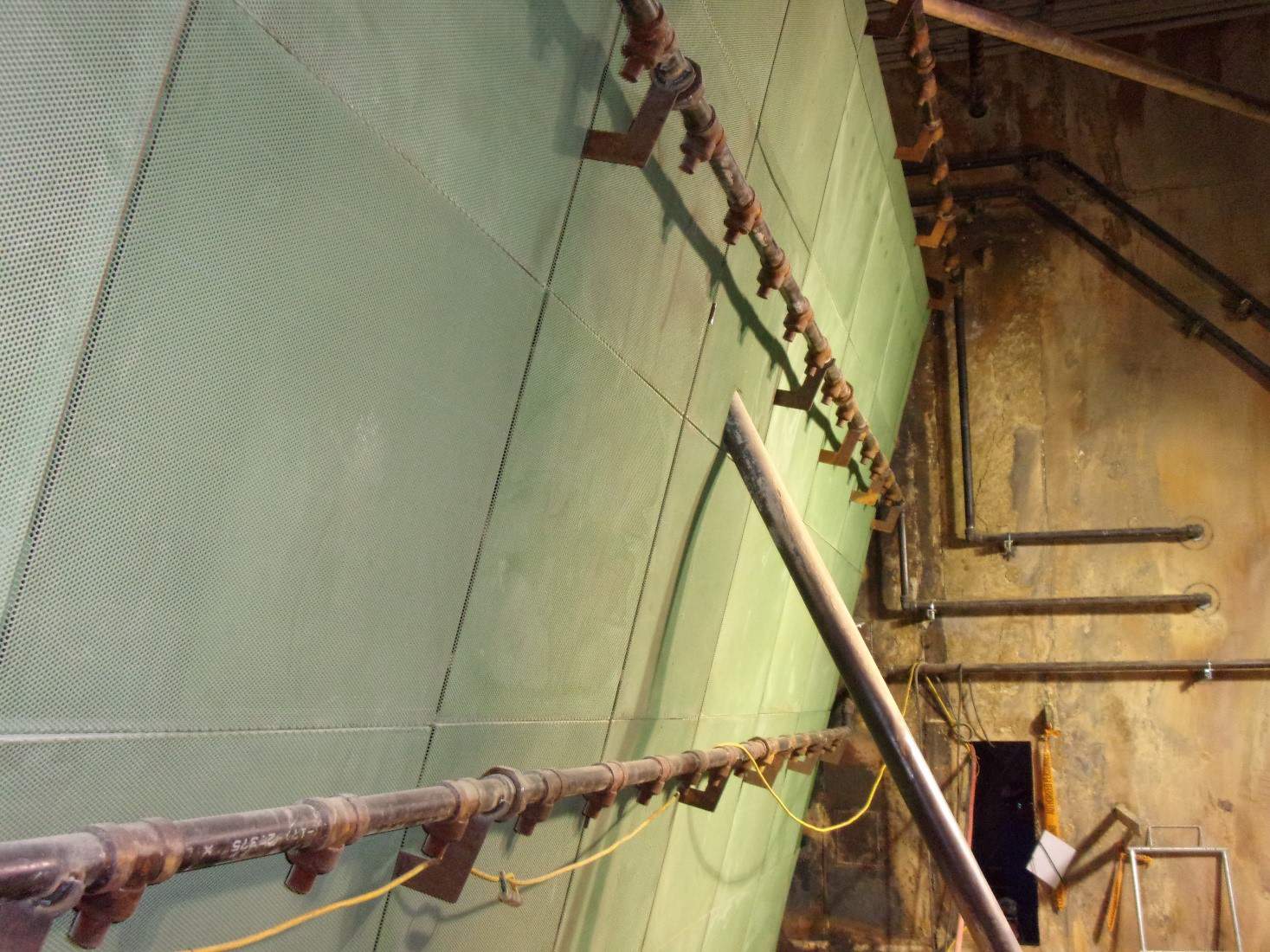

All SCR air cannon nozzles are not created equal. IGS has spent significant time developing ideal nozzles for SCR applications. This High-Efficiency fan jet nozzle eliminates the «shadow» region between nozzles, as seen with the typical fan jet nozzle. This also maximizes the cross-sweeping pattern to remove deposits and distribute fly ash more effectively.

IGS offers a wide range of nozzle designs engineered for their specific application. These include wide-sweeping High-Efficiency Fan Jet nozzles for light buildup over a large area, powerful High-Velocity nozzles to break up dense materials, Header Nozzle Systems for short, powerful blasts over a long distance, and everything in between. Watch the video to find out more.

In the environment that air cannons are installed in, you can count on the fact the process changes will affect the buildup. Changing buildup affects the performance of the air cannons.

Sometimes the buildup may become too difficult for the air cannon to handle. Or the air cannon will be out of service and allows the buildup to become stronger than the air cannon blast. This is why IGS has developed the MEGA Blast. We have discovered the path to increasing the cleaning of your air cannon blast by up to 5 times.

We can train your personnel on how this can be accomplished using a safe and straightforward method. Let your air cannons control the buildup on a daily basis, and when trouble needs to be controlled, call in the MEGA Blast. In less than one hour, the MEGA Blast will blast away the toughest blockage.

The IGS BIG BLUE redundancy option allows the system to never be taken out of service when an air cannon requires maintenance. Three knife gates are added to the system, one at the discharge of each air cannon, and one in the middle of the system.

An air cannon should be operated regularly to ensure it does not freeze up from sitting exposed to elements. Therefore this system utilizes both air cannons under normal conditions, with the right and left sides isolated by the slide gate in the middle, which is typically closed.

If an air cannon is taken out of service, the slide gate nearest to this air cannon is closed, and the center slide gate opened. This isolates the air cannon in need of repair and allows the one air cannon left in service to operate all discharges.

The IGS Air Cannon Monitoring System utilizes proximity switches to verify the proper operation of the air cylinders on both the air cannons and the multiplier units. It incorporates one pressure transmitter on the receiver tank itself.

IGS will supply engineering support to help write the logic for the DCS to show proper system operation, which will set off a notification alarm if the system malfunctions. This can also be used to pinpoint the location of the issue, allowing for more rapid diagnosis and maintenance.

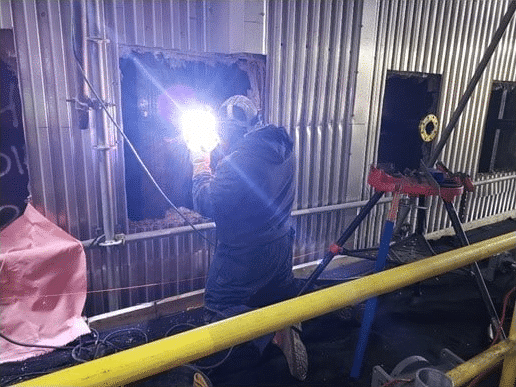

IGS offers installation and/or onsite engineering supervision packages for all of our equipment. Experience with designing and installing online cleaning systems is the key to a successful and efficient installation. IGS’s expertise saves time and money during installation, ensuring the equipment is installed the first time correctly, in the most cost-effective manner possible.

Proper installation is critical for air cannon systems, especially concerning the alignment of the nozzles. All nozzles must be evenly aligned parallel across the surface of the catalyst module.

If this is not accomplished, the system’s efficiency will be reduced, and in some cases, nozzle misalignment can cause catalyst damage. IGS can guarantee no catalyst damage will occur with complete turnkey installation and laser alignment process.

IGS utilizes a proprietary laser alignment system to ensure proper nozzle alignment during installation. This technology will be included with either a turnkey installation or installation supervision. The IGS mechanical team also has unmatched installation experience and knowledge with our systems and boasts a high level of attention to detail.

IGS is here to provide information, answer questions and create an effective solution for your needs.