Boiler Deslagging

IGS Anti-Slagging Technology for Coal Fired Boilers

Anti-Slag and Fouling Properties of the Ceramic Coating Surface

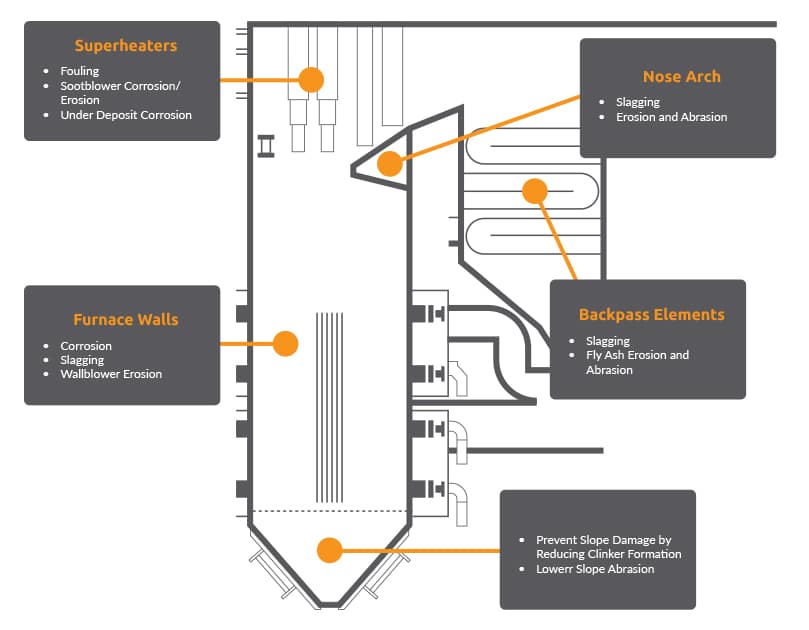

IGS anti-slagging, or boiler deslagging, technology bonds tightly to the boiler tube’s surface, creating a non-porous, non-wetting, non-reactive surface. The coating will significantly limit molten slags from bonding to the surface, reducing slag and fouling agglomerations. Waterwall furnace tubes and Superheater tubes can benefit from being protected with the IGS coatings. IGS has developed a series of ceramic coating formulations which are modified to match a specific tubes properties and excel in a specific boiler environment.

What benefits can you expect from IGS’ Boiler Deslagging technology?

Increased Heat Rate, Lower Furnace Gas Exit Temperatures (FGET)

IGS ceramic coatings can help increase heat absorption into boiler tubes by reducing the amount of slag or fouling on the OD surface of the tube, and by eliminating the formation of corrosion scales on the tubes surface.

The coating itself exhibits high thermal conductivity and high emissivity, which means the coating layer will not insulate the tubes. A coated tube will have higher heat absorption compared to an un-coated scaled tube. It is possible to rebalance a boiler that is suffering from severe slagging or fouling. The lower FGET is possible by absorbing more heat into the waterwalls while achieving the same final steam temp (reduced fuel input, same final steam temp, reduced waste heat) is even possible to help address boilers that have de-rated their MW output capacity due to superheater fouling.

Get in touch for expert Boiler Deslagging and Fouling advice in <8 hours

Reduced Damage from Soot blowers and Watercannons

By significantly reducing the amount of slag or fouling on a tubes surface, it is possible to greatly reduce the frequency at which soot blowers or water cannons are activated. Because there will be less slag attached on the tubes, lowering heat absorption, there’s no need to continuously run the slag control equipment. When soot blowers or retractable lances remove slag and fouling, the tube itself will be thermally shocked due to the removal of the dirty insulating material, creating the potential for circumferential cracking or corrosion assisted fatigue (CAF) of the tube. Reducing soot blower usage inhibits this, and slows the wasting of the tubes surfaces.

Reduced Insulating PRB White Reflective Fly Ash

IGS offers solutions for the most challenging environments and always works with our customers to address their unique needs. For example, when facilities burn sub-bituminous coal, such as coal mined from the Powder River Basin in the northwest region of the US, it can create a thick layer of alumina known as white reflective fly ash. This ash is sticky and poses many problems to boiler operators, especially in units that have been converted to handle this type of coal from another type of coal. The ash fusion temperature is lower compared to other coals, and the slag is incredibly sticky, leading to significant superheater fouling and possible boiler derating. By re-engineering the surface with an advanced coating technology, we can reduce these maintenance challenges.

For more information on these ceramic coating products for Power Generation, please contact one of our product specialists.

What is Boiler Slagging and Deslagging?

Power boilers experience slagging as the molten ash adheres to the surrounding substrates. This is also commonly referred to as slag. The amount of slag is primarily dependent on temperature and the types of coal being used and whether it is anthracite, bituminous coal, subbituminous coal, or lignite. Boilers will often slag in the upper sections of the furnace where the temperatures are higher near the superheat pendants, but slagging may also occur on the waterwalls. Many utilities have installed soot blowers to control the amount of slag, as it has a negative effect on boiler operation. The slag acts as an insulation to the tube substrate and this loss of heat transfer is not optimal. When the slag builds up on the tubes, the heat transfer decreases lowering the temperature of the steam going to the superheated portion of the system, therefore decreasing the overall efficiency of the system. Finding a solution to excessive slagging can have tremendous benefits for a boiler operators bottom line.

Watch IGS Case Study: Pulverised Coal Boiler Deslagging

How can boiler corrosion be prevented?

Boiler corrosion, erosion or metal loss can be prevented by changing the boiler’s operating conditions and protecting the tube surface from the combustion environment. IGS’ HVTS® – a High Velocity Thermal Spray cladding can serve as a protective barrier eliminating further wastage.

On-Site HVTS® Cladding Mitigating Boiler Fireside Corrosion

For PC-Fired Boilers, IGS applies high alloy materials to produce a homogenous (particles typically <50um) coating. The coating displays ultra low permeability to corrosive media that optimizes its performance in Coal Boilers.

IGS HVTS®

IGS High Velocity Thermal Spray cladding is ideal for long-term, reliable protection from the above described typical wastage mechanisms. We designed the cladding composition in the mid-2000’s specifically for high temperature sulfidation environments with the understanding that permeation and oxide content should be below critical specified levels for long term cladding performance.

Our HVTS® is a High Velocity, low stress state, thermal sprayed Metalspray® specifically suited for boiler tube protection in combustion environments with aggressive sulfidation conditions up to 1800°F (980°C). It is highly protective against under deposit corrosion, when Sulfur together with Sodium, Potassium and Vanadium Oxides form low melting temperature pyro-eutectic salts. The high Chromium content, together with performance enhancing elements provide a dense stable coating, with high bond strength due to micro-fusion sites on the substrate. A thermal expansion coefficient at the midpoint between carbon and stainless steels makes it well suited to both as substrate materials. The material also has good erosion resistance due to effective hard-phase integration.

IGS HVTS® was also tested by world renowned EPRI, Electric Power Research Institute, in a 1,300MW high sulfur coal, Supercritical boiler. Several other competitor’s materials were also tested, and IGS HVTS® was the ONLY material to fully protect the substrate from corrosion during the 39,000 hour testing period.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.