Eliminación de Sarro en Tubos Durante la Operación

Es posible que necesite una limpieza de sarro en tubos calientes si la sección radiante alcanza sus límites de diseño, como la temperatura de la pared de puente (Bridgewall)

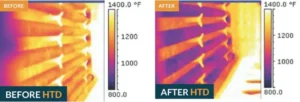

El aumento de la temperatura de la pared de puente puede ser un síntoma de ensuciamiento excesivo en los tubos radiantes. Estos tubos de aleación de acero tienden a oxidarse bajo condiciones de operación. Con el tiempo, se forman capas de sarro que aíslan el lado expuesto al fuego del tubo, impidiendo la transferencia eficaz del calor radiante. Esta situación se vuelve aún más problemática si faltan varios años para la próxima parada programada.

Eliminación de Sarro en Tubos Durante la Operación

El proceso patentado de Eliminación de Sarro en Tubos de Hot-tek remueve el sarro y el ensuciamiento del lado expuesto al fuego de los tubos de proceso en la sección radiante sin necesidad de apagar el horno. Nuestro proceso se realiza en línea, utilizando lanzas patentadas con enfriamiento por agua para garantizar una limpieza segura y continua mientras el calentador sigue en funcionamiento normal.

Se emplea un medio abrasivo consumible que no genera aumento en la opacidad.

Resultados Típicos del Proceso de Eliminación de Sarro en Línea

- Reducción de la temperatura de la pared de puente entre 50 °F (10 °C) y 100 °F (38 °C)

- Retorno rápido de la inversión, comprobado por múltiples clientes

- Servicio complementario de recubrimiento de tubos, que previene la oxidación y formación de sarro por 8 a 10 años

Para ciertas aplicaciones, utilizamos el sistema Lancescope™ de Hot-tek para inspeccionar zonas de difícil acceso. También ofrecemos la instalación de puertos de acceso diseñados de forma segura, que facilitan el proceso de limpieza en línea y futuras intervenciones.

Antes y Después de la Desincrustación de Tubos Calientes

Consulta Gratuita con un Experto en la Materia de IGS

IGS está aquí para proporcionar información, responder preguntas y crear una solución efectiva para sus necesidades.