We provide effective strategies to optimize Selective Catalytic Reduction (SCR) systems utilized by major Petrochemical, Oil & Gas, and Power Plants around the world. Whether you’re facing challenges related to ammonia slip, SCR fouling, our innovative solutions can help improve SCR performance and ensure compliance with environmental regulations.

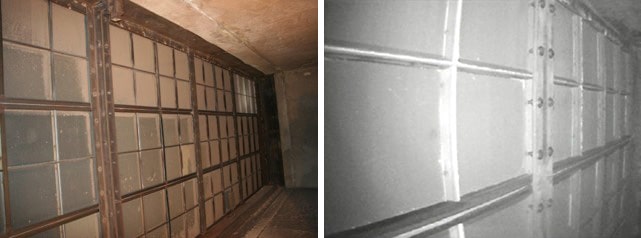

Blockages within SCR systems can disrupt gas flow, compromise catalyst performance, and reduce NOx reduction efficiency. Our solution focuses on proactive measures to prevent blockages and effectively resolve existing blockage issues. By optimizing gas flow and restoring catalyst functionality, our approach ensures consistent SCR performance and improved emission control.

Fouling can impair catalyst effectiveness and hinder the overall performance of an SCR system. Our comprehensive solution combats SCR fouling, extending catalyst lifespan and maintaining optimal system efficiency. Through innovative techniques and advanced cleaning methodologies, we remove fouling contaminants and restore SCR performance, enabling efficient NOx reduction and compliance with emission standards.

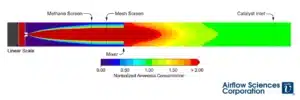

Ammonia slip can hinder SCR efficiency and contribute to emissions issues. Our specialized solution addresses this challenge by ensuring proper NOx distribution as the flue gas approaches the ammonia injection system by eliminating flue gas disruption due to material fouling to maximize the reaction rate, resulting in improved DeNOx performance, reduction of require ammonia, and reduction of ammonia slip. Experience enhanced emissions control and increased operational efficiency with our tailored approach to ammonia slip reduction.

Our solutions have a track record of delivering tangible improvements in SCR performance and emissions control.

We understand that each SCR system is unique, and our solutions are customized to address specific challenges and optimize performance according to your system’s requirements.

We leverage cutting-edge technologies to provide innovative solutions that exceed industry standards and deliver exceptional results.

Our solutions not only enhance SCR performance but also ensure compliance with environmental regulations, reducing emissions and minimizing environmental impact.

If you’re encountering challenges related to ammonia slip, material accumulation, emissions restrictions or fouling in your SCR system, we can help. Contact us today to discuss your specific requirements and explore how our SCR performance solutions can optimize your system, improve efficiency, and ensure compliance with environmental regulations.

Unlock the full potential of your SCR system with our proven solutions. Experience enhanced performance, improved emissions control, and operational efficiency by implementing our tailored SCR performance solutions.

IGS is here to provide information, answer questions and create an effective solution for your needs.